Table of Contents

Analyzing the Global Pressure Transmitter Market Share: What Factors are Driving Growth?

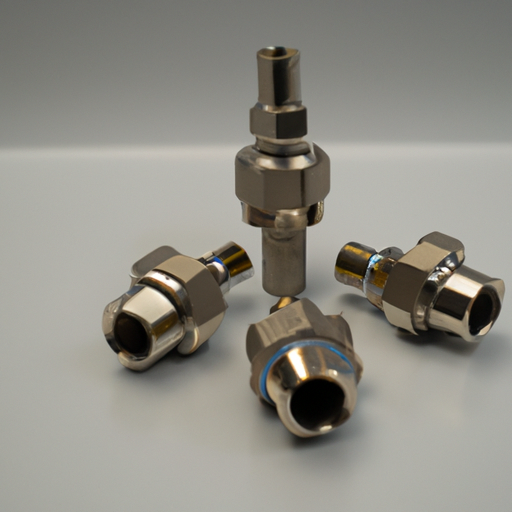

The global pressure transmitter market is on the rise, and there are a few key factors driving its growth. From increased demand for automation in industrial processes to the development of new technologies, the pressure transmitter market is poised for continued growth in the coming years. First, the demand for automation in industrial processes is driving the growth of the pressure transmitter market. Automation is becoming increasingly important in industrial processes, and pressure transmitters are essential components of automated systems. Pressure transmitters are used to measure and monitor pressure in a variety of industrial applications, from oil and gas production to water treatment. As automation becomes more widespread, the demand for pressure transmitters is expected to increase. Second, the development of new technologies is also driving the growth of the pressure transmitter market. Advances in technology have enabled the development of more accurate and reliable pressure transmitters. This has allowed manufacturers to produce more efficient and cost-effective pressure transmitters, which has increased their popularity among industrial users.Exploring the Impact of Factory Automation on Pressure Transmitter Market Share: What Can We Learn?

Factory automation is becoming increasingly popular in the industrial sector, and its impact on the pressure transmitter market share is undeniable. In this article, we’ll explore what we can learn from the impact of factory automation on pressure transmitter market share. First, it’s important to understand what factory automation is and how it works. Factory automation is the use of automated systems to control and monitor the production process in a factory. This includes the use of robots, sensors, and other automated systems to automate the production process. This automation can help reduce costs, increase efficiency, and improve product quality.

The impact of factory automation on pressure transmitter market share is significant. Automation can reduce the cost of production, as well as the time it takes to produce a product. This can lead to increased market share for pressure transmitters, as they become more affordable and easier to use. Automation can also reduce the need for manual labor, which can lead to a decrease in labor costs.

In addition, automation can improve product quality. Automated systems can detect and correct errors in the production process, which can lead to improved product quality. This can lead to increased customer satisfaction and increased market share for pressure transmitters.

First, it’s important to understand what factory automation is and how it works. Factory automation is the use of automated systems to control and monitor the production process in a factory. This includes the use of robots, sensors, and other automated systems to automate the production process. This automation can help reduce costs, increase efficiency, and improve product quality.

The impact of factory automation on pressure transmitter market share is significant. Automation can reduce the cost of production, as well as the time it takes to produce a product. This can lead to increased market share for pressure transmitters, as they become more affordable and easier to use. Automation can also reduce the need for manual labor, which can lead to a decrease in labor costs.

In addition, automation can improve product quality. Automated systems can detect and correct errors in the production process, which can lead to improved product quality. This can lead to increased customer satisfaction and increased market share for pressure transmitters.

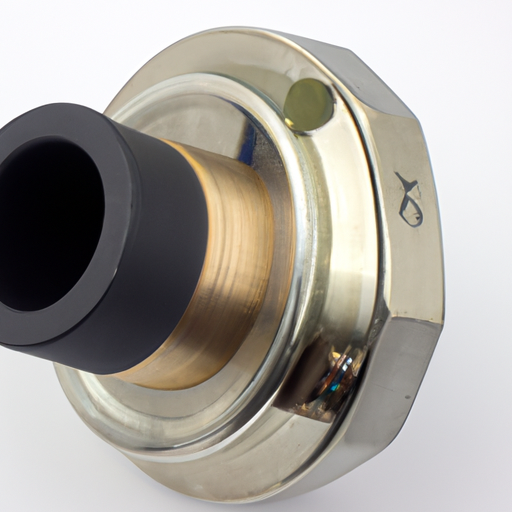

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |