Introduction to Pressure Transducer Sensor Arduino Code

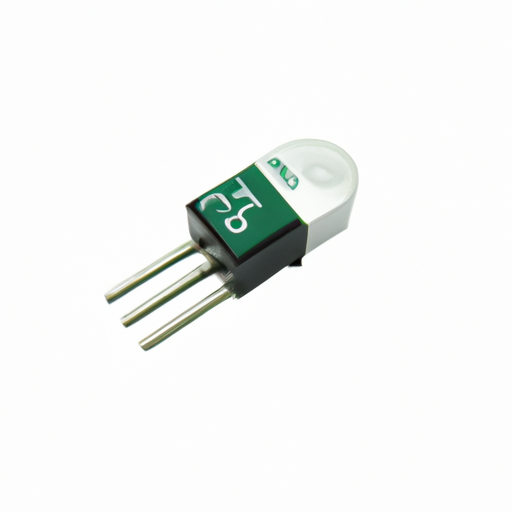

Pressure Transducer Sensor Arduino Code: A Comprehensive Introduction Pressure transducer sensors have become an integral part of various industries, enabling accurate measurement and monitoring of pressure levels. These sensors are widely used in applications such as automotive, aerospace, and industrial automation. To harness the full potential of pressure transducer sensors, it is essential to understand the Arduino code that drives them. In this article, we will delve into the intricacies of pressure transducer sensor Arduino code, exploring its significance and the best wholesaler in China.

Arduino, an open-source electronics platform, provides a flexible and user-friendly environment for programming pressure transducer sensors. The Arduino code acts as the bridge between the sensor and the microcontroller, facilitating the conversion of analog pressure readings into digital data. This code is crucial for configuring the sensor, calibrating its output, and implementing various functionalities.

When it comes to pressure transducer sensor Arduino code, China has emerged as a leading player in the market. Chinese wholesalers offer a wide range of high-quality pressure transducer sensors and associated Arduino code at competitive prices. These wholesalers have gained a reputation for their reliability, efficiency, and commitment to customer satisfaction.

To effectively utilize pressure transducer sensors, it is essential to understand the Arduino code that accompanies them. The code typically consists of a series of instructions that define the sensor’s behavior and functionality. It includes commands for initializing the sensor, reading analog voltage values, and converting them into pressure units. Additionally, the code may incorporate calibration routines to ensure accurate measurements.

One of the key aspects of pressure transducer sensor Arduino code is the calibration process. Calibration allows for the adjustment of sensor readings to account for any inherent inaccuracies or variations. This ensures that the sensor provides precise and reliable pressure measurements. The Arduino code facilitates the calibration process by providing the necessary functions and algorithms to determine the calibration coefficients.

Implementing pressure transducer sensor Arduino code involves a step-by-step process. First, the code must be uploaded to the Arduino microcontroller using the Arduino Integrated Development Environment (IDE). Once uploaded, the code establishes communication with the pressure transducer sensor and configures its settings. The code then continuously reads the analog voltage output from the sensor and converts it into pressure units using the calibration coefficients.

Arduino, an open-source electronics platform, provides a flexible and user-friendly environment for programming pressure transducer sensors. The Arduino code acts as the bridge between the sensor and the microcontroller, facilitating the conversion of analog pressure readings into digital data. This code is crucial for configuring the sensor, calibrating its output, and implementing various functionalities.

When it comes to pressure transducer sensor Arduino code, China has emerged as a leading player in the market. Chinese wholesalers offer a wide range of high-quality pressure transducer sensors and associated Arduino code at competitive prices. These wholesalers have gained a reputation for their reliability, efficiency, and commitment to customer satisfaction.

To effectively utilize pressure transducer sensors, it is essential to understand the Arduino code that accompanies them. The code typically consists of a series of instructions that define the sensor’s behavior and functionality. It includes commands for initializing the sensor, reading analog voltage values, and converting them into pressure units. Additionally, the code may incorporate calibration routines to ensure accurate measurements.

One of the key aspects of pressure transducer sensor Arduino code is the calibration process. Calibration allows for the adjustment of sensor readings to account for any inherent inaccuracies or variations. This ensures that the sensor provides precise and reliable pressure measurements. The Arduino code facilitates the calibration process by providing the necessary functions and algorithms to determine the calibration coefficients.

Implementing pressure transducer sensor Arduino code involves a step-by-step process. First, the code must be uploaded to the Arduino microcontroller using the Arduino Integrated Development Environment (IDE). Once uploaded, the code establishes communication with the pressure transducer sensor and configures its settings. The code then continuously reads the analog voltage output from the sensor and converts it into pressure units using the calibration coefficients.

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |