Introduction to Pressure Transducer Principle

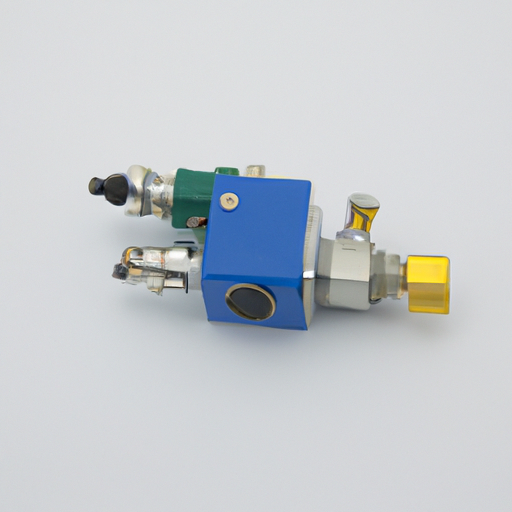

Pressure Transducer Principle: An Introduction to China’s High-Grade Wholesaler Pressure transducers are essential devices used in various industries to measure and monitor pressure levels accurately. These devices play a crucial role in ensuring the safety and efficiency of many processes. In China, a high-grade wholesaler offers pressure transducers that adhere to the highest standards of quality and reliability. In this article, we will delve into the principle behind pressure transducers and explore why this Chinese wholesaler is a trusted source for these devices. At its core, a pressure transducer is a sensor that converts pressure into an electrical signal. It measures the force exerted on it by a fluid or gas and translates it into an output voltage or current proportional to the applied pressure. This principle is based on the concept of piezoresistivity, which states that certain materials change their electrical resistance when subjected to mechanical stress. The pressure transducer consists of a diaphragm made of a piezoresistive material, such as silicon. When pressure is applied to the diaphragm, it deforms, causing a change in the resistance of the material. This change in resistance is then converted into an electrical signal by a Wheatstone bridge circuit, which amplifies and processes the signal for further use.

China’s high-grade wholesaler understands the importance of using quality materials in pressure transducers. They ensure that their devices are made with precision and accuracy, using advanced manufacturing techniques. This commitment to quality ensures that the pressure transducers they offer are reliable and provide accurate measurements in various applications.

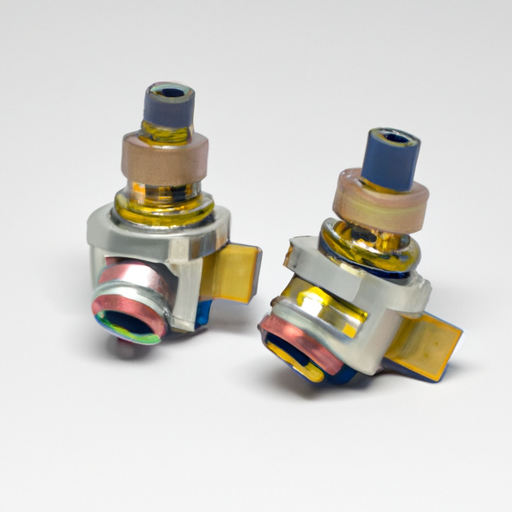

One of the key advantages of pressure transducers is their ability to measure pressure across a wide range. They can accurately measure both low and high-pressure levels, making them suitable for a diverse range of industries. Whether it’s monitoring the pressure in a hydraulic system or measuring the pressure in a gas pipeline, pressure transducers offer the versatility needed for different applications.

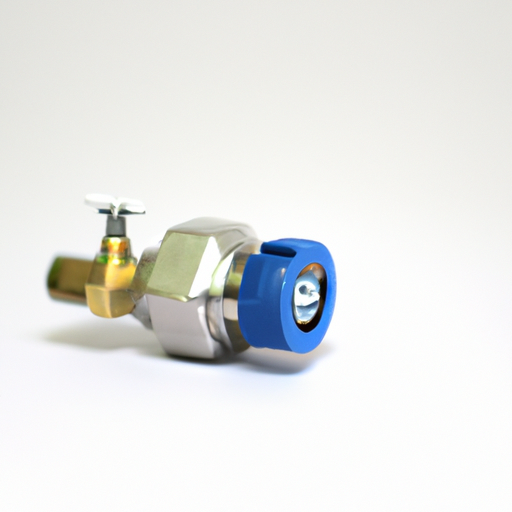

Furthermore, pressure transducers are known for their high sensitivity and responsiveness. They can detect even the slightest changes in pressure, allowing for real-time monitoring and control. This capability is crucial in industries where maintaining precise pressure levels is essential for safety and efficiency.

China’s high-grade wholesaler understands the importance of using quality materials in pressure transducers. They ensure that their devices are made with precision and accuracy, using advanced manufacturing techniques. This commitment to quality ensures that the pressure transducers they offer are reliable and provide accurate measurements in various applications.

One of the key advantages of pressure transducers is their ability to measure pressure across a wide range. They can accurately measure both low and high-pressure levels, making them suitable for a diverse range of industries. Whether it’s monitoring the pressure in a hydraulic system or measuring the pressure in a gas pipeline, pressure transducers offer the versatility needed for different applications.

Furthermore, pressure transducers are known for their high sensitivity and responsiveness. They can detect even the slightest changes in pressure, allowing for real-time monitoring and control. This capability is crucial in industries where maintaining precise pressure levels is essential for safety and efficiency.

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |