Table of Contents

How Barometric Industrial Pressure Sensors Can Help Improve Efficiency in Manufacturing

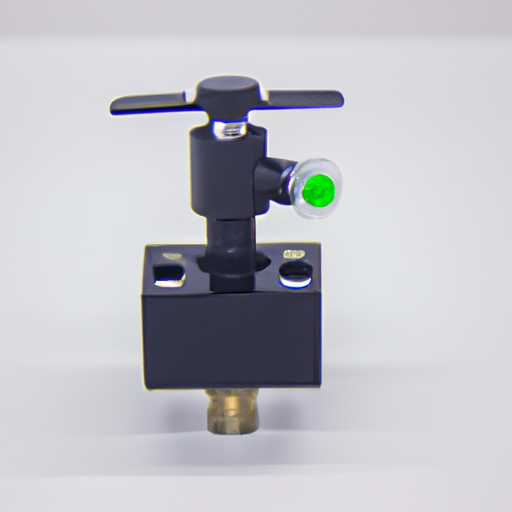

Barometric industrial pressure sensors are a valuable tool for improving efficiency in manufacturing. These sensors measure the atmospheric pressure in a given environment, allowing manufacturers to make informed decisions about their production processes. By monitoring the pressure, manufacturers can adjust their processes to ensure optimal performance and efficiency. The barometric industrial pressure sensor is a highly accurate device that can detect even the slightest changes in atmospheric pressure. This allows manufacturers to make adjustments to their production processes in order to maximize efficiency. For example, if the pressure is too low, the manufacturer can adjust the speed of the production line to ensure that the product is produced at the optimal rate. Similarly, if the pressure is too high, the manufacturer can adjust the speed of the production line to reduce the amount of energy used. In addition to improving efficiency, barometric industrial pressure sensors can also help manufacturers reduce their environmental impact. By monitoring the pressure, manufacturers can adjust their processes to reduce emissions and conserve energy. This can help manufacturers meet their sustainability goals and reduce their carbon footprint.

Overall, barometric industrial pressure sensors are a valuable tool for improving efficiency in manufacturing. By monitoring the atmospheric pressure, manufacturers can make informed decisions about their production processes and reduce their environmental impact. With the help of these sensors, manufacturers can ensure that their production processes are running at optimal levels and that their products are produced in an efficient and sustainable manner.

In addition to improving efficiency, barometric industrial pressure sensors can also help manufacturers reduce their environmental impact. By monitoring the pressure, manufacturers can adjust their processes to reduce emissions and conserve energy. This can help manufacturers meet their sustainability goals and reduce their carbon footprint.

Overall, barometric industrial pressure sensors are a valuable tool for improving efficiency in manufacturing. By monitoring the atmospheric pressure, manufacturers can make informed decisions about their production processes and reduce their environmental impact. With the help of these sensors, manufacturers can ensure that their production processes are running at optimal levels and that their products are produced in an efficient and sustainable manner.The Benefits of Working with a Reputable Barometric Industrial Pressure Sensors Supplier

When it comes to finding the right barometric industrial pressure sensors supplier, it pays to work with a reputable one. A reputable supplier will provide you with quality products that are reliable and accurate. They will also provide you with excellent customer service and technical support. Here are some of the benefits of working with a reputable barometric industrial pressure sensors supplier. First, you can be sure that the products you purchase are of the highest quality. Reputable suppliers use only the best materials and components to ensure that their products are reliable and accurate. This means that you can trust the readings you get from the sensors and that you can rely on them to provide accurate readings.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |