Table of Contents

Exploring the Benefits of Pressure Sensor Matrix Technology in Chinese Manufacturing

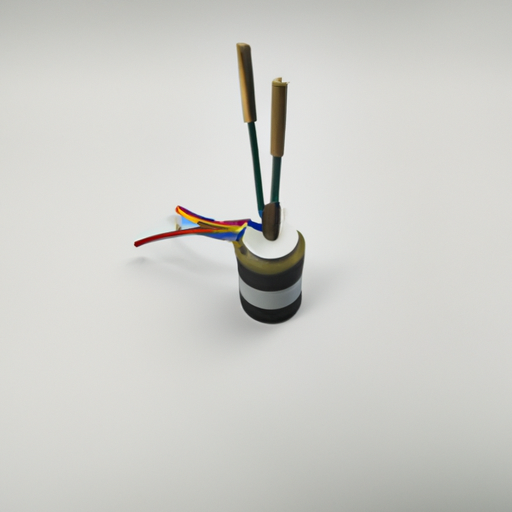

The use of pressure sensor matrix technology in Chinese manufacturing is becoming increasingly popular due to its numerous benefits. Pressure sensor matrix technology is a type of sensing technology that uses a matrix of pressure sensors to measure the pressure distribution of a surface. This technology is used in a variety of applications, including automotive, medical, and industrial manufacturing. In Chinese manufacturing, pressure sensor matrix technology can be used to improve the accuracy and efficiency of production processes. By measuring the pressure distribution of a surface, manufacturers can identify areas of high and low pressure, allowing them to adjust the pressure applied to the surface accordingly. This can help to reduce the amount of time and energy required to complete a task, as well as improve the quality of the finished product. Overall, pressure sensor matrix technology can provide numerous benefits to Chinese manufacturing. By measuring the pressure distribution of a surface, manufacturers can identify areas of high and low pressure, allowing them to adjust the pressure applied to the surface accordingly. This can help to reduce the amount of time and energy required to complete a task, as well as improve the quality of the finished product. In addition, pressure sensor matrix technology can be used to detect defects in products and improve safety in the workplace. As such, pressure sensor matrix technology is an invaluable tool for Chinese manufacturers.

Overall, pressure sensor matrix technology can provide numerous benefits to Chinese manufacturing. By measuring the pressure distribution of a surface, manufacturers can identify areas of high and low pressure, allowing them to adjust the pressure applied to the surface accordingly. This can help to reduce the amount of time and energy required to complete a task, as well as improve the quality of the finished product. In addition, pressure sensor matrix technology can be used to detect defects in products and improve safety in the workplace. As such, pressure sensor matrix technology is an invaluable tool for Chinese manufacturers.How Pressure Sensor Matrix Technology is Revolutionizing Quality Control in Chinese Factories

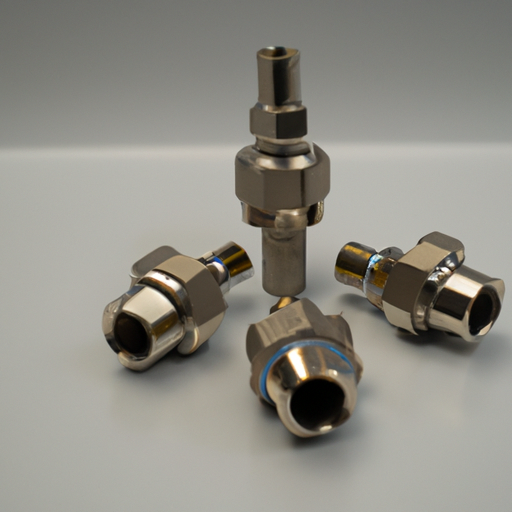

Pressure sensor matrix technology is revolutionizing quality control in Chinese factories. This technology is a game-changer for the manufacturing industry, as it allows for the precise measurement of pressure distribution across a surface. This technology is being used to detect defects in products, such as uneven pressure distribution, which can lead to product failure. The pressure sensor matrix technology works by using a network of sensors to measure the pressure distribution across a surface. The sensors are connected to a computer, which then processes the data and provides a detailed analysis of the pressure distribution. This analysis can be used to detect any irregularities in the pressure distribution, which can indicate a defect in the product.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |