Table of Contents

Exploring the Benefits of Pressure Sensor Array Technology for Industrial Applications

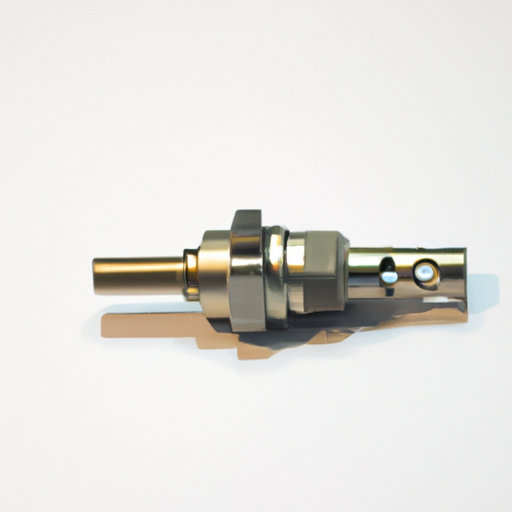

Pressure sensor array technology is becoming increasingly popular in industrial applications due to its many benefits. Pressure sensor arrays are composed of multiple pressure sensors that are connected together to measure pressure in a variety of ways. This technology offers a number of advantages over traditional pressure sensors, including improved accuracy, faster response times, and increased flexibility. One of the main benefits of pressure sensor array technology is improved accuracy. By using multiple sensors, the system can measure pressure more accurately than a single sensor. This is especially important in industrial applications where precise measurements are essential. Additionally, the sensors can be calibrated to measure different pressures, allowing for greater flexibility. Another advantage of pressure sensor array technology is faster response times. By using multiple sensors, the system can quickly detect changes in pressure and respond accordingly. This is especially useful in applications where quick response times are critical, such as in the automotive industry. Finally, pressure sensor array technology offers increased flexibility. By using multiple sensors, the system can be configured to measure different pressures in different locations. This allows for greater customization and can be used to measure pressure in hard-to-reach places.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

How Pressure Sensor Array Companies are Revolutionizing Automotive Manufacturing

Pressure sensor array companies are revolutionizing automotive manufacturing by providing a more efficient and accurate way to measure and monitor pressure. Pressure sensors are used in a variety of automotive applications, such as engine control, fuel injection, and brake systems. By using pressure sensor arrays, manufacturers can measure and monitor pressure more accurately and quickly than ever before. The use of pressure sensor arrays also allows for more efficient production. By having multiple sensors in different locations, manufacturers can quickly identify any issues with the vehicle’s performance and make adjustments accordingly. This reduces the amount of time and money spent on production, as well as the amount of waste created.

Overall, pressure sensor array companies are revolutionizing automotive manufacturing by providing a more efficient and accurate way to measure and monitor pressure. This technology is helping to reduce production costs and waste, while also improving the performance of vehicles.

The use of pressure sensor arrays also allows for more efficient production. By having multiple sensors in different locations, manufacturers can quickly identify any issues with the vehicle’s performance and make adjustments accordingly. This reduces the amount of time and money spent on production, as well as the amount of waste created.

Overall, pressure sensor array companies are revolutionizing automotive manufacturing by providing a more efficient and accurate way to measure and monitor pressure. This technology is helping to reduce production costs and waste, while also improving the performance of vehicles.