Table of Contents

How Differential Pressure Sensors from Chinese Manufacturers are Revolutionizing Industrial Automation

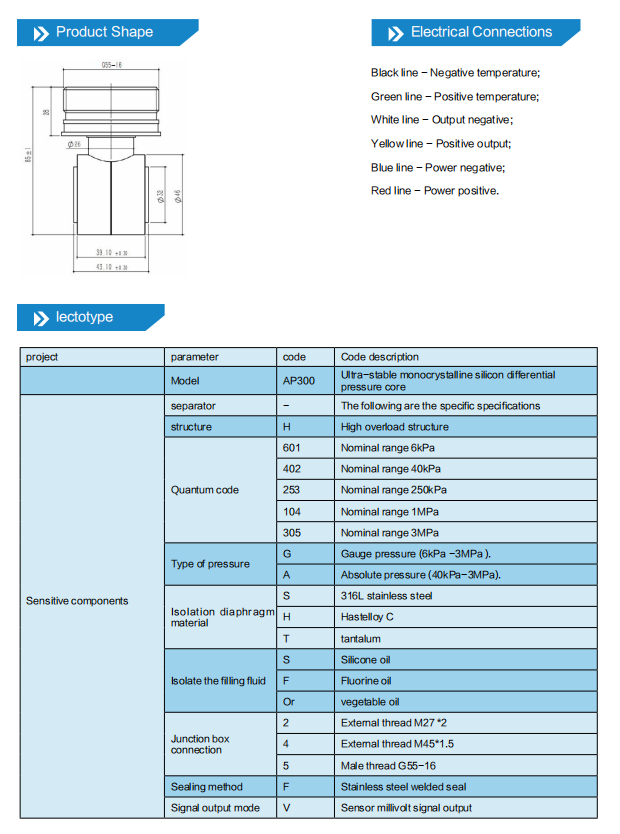

Person 1: Have you heard about the new differential pressure sensors from Chinese manufacturers? Person 2: No, I haven’t. What are they?| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

Exploring the Benefits of Differential Pressure Sensors from Chinese Manufacturers for HVAC Applications

Person 1: Have you heard about differential pressure sensors? Person 2: No, I haven’t. What are they? Person 1: Differential pressure sensors are used in HVAC applications to measure the difference in pressure between two points. They are used to measure air flow, filter status, and other parameters. Person 2: That sounds interesting. Where can I find them? Person 1: You can find them from Chinese manufacturers. They offer a wide range of products with different features and capabilities. Person 1: The main benefit is cost savings. Chinese manufacturers offer competitive prices and high quality products. They also offer a wide range of customization options, so you can get the exact product you need. Additionally, they offer fast delivery times and excellent customer service.

Person 1: The main benefit is cost savings. Chinese manufacturers offer competitive prices and high quality products. They also offer a wide range of customization options, so you can get the exact product you need. Additionally, they offer fast delivery times and excellent customer service.