Table of Contents

How Chinese Companies are Leveraging Pressure Sensors to Improve Industrial Efficiency

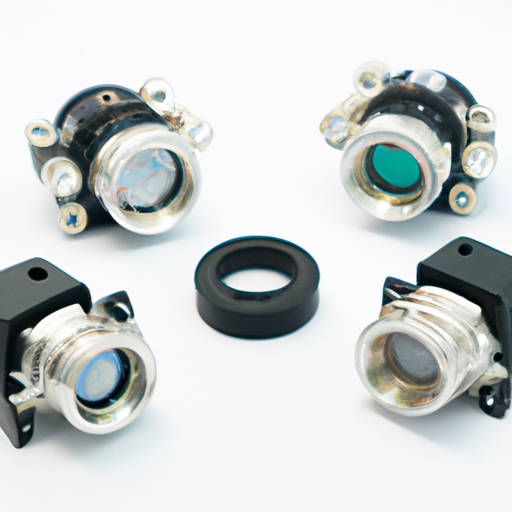

Chinese companies are increasingly leveraging pressure sensors to improve industrial efficiency. Pressure sensors are devices that measure the pressure of a gas or liquid and convert it into an electrical signal. They are used in a variety of industrial applications, such as controlling the flow of fluids, monitoring the pressure of a system, and detecting leaks. The use of pressure sensors in Chinese industries has grown significantly in recent years. This is due to the fact that they are relatively inexpensive and easy to install. Additionally, they provide accurate readings and can be used to monitor a wide range of parameters. This makes them ideal for industrial applications. One of the most common uses of pressure sensors in Chinese industries is to monitor the pressure of a system. This is especially important in the manufacturing process, as it helps to ensure that the system is operating at the correct pressure. Pressure sensors can also be used to detect leaks in a system, which can help to reduce downtime and improve efficiency.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

Exploring the Benefits of Pressure Sensors for Industrial Applications in China

Pressure sensors are becoming increasingly popular in industrial applications in China. These devices are used to measure the pressure of liquids and gases, and they can be used in a variety of industries, from automotive to medical. Pressure sensors offer a number of benefits that make them an attractive option for industrial applications in China. First, pressure sensors are highly accurate. They can measure pressure with a high degree of precision, which is essential for many industrial applications. This accuracy helps to ensure that the products produced are of the highest quality. Second, pressure sensors are reliable. They are designed to withstand harsh conditions, such as extreme temperatures and vibrations. This makes them ideal for use in industrial settings, where reliability is essential. Fourth, pressure sensors are easy to install and maintain. They require minimal setup and maintenance, which makes them a great choice for industrial applications.

Finally, pressure sensors are versatile. They can be used in a variety of applications, from automotive to medical. This makes them a great choice for industrial applications in China.

Overall, pressure sensors offer a number of benefits that make them an attractive option for industrial applications in China. They are accurate, reliable, cost-effective, easy to install and maintain, and versatile. These benefits make pressure sensors a great choice for industrial applications in China.

Fourth, pressure sensors are easy to install and maintain. They require minimal setup and maintenance, which makes them a great choice for industrial applications.

Finally, pressure sensors are versatile. They can be used in a variety of applications, from automotive to medical. This makes them a great choice for industrial applications in China.

Overall, pressure sensors offer a number of benefits that make them an attractive option for industrial applications in China. They are accurate, reliable, cost-effective, easy to install and maintain, and versatile. These benefits make pressure sensors a great choice for industrial applications in China.