Table of Contents

How to Ensure Quality Control in Pressure Transmitter Testing Factories

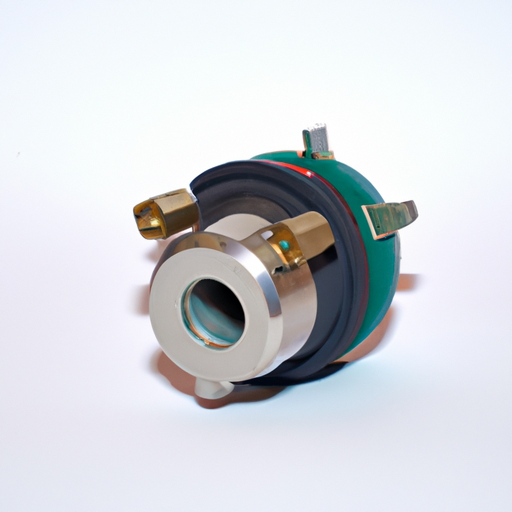

Quality control is essential in pressure transmitter testing factories to ensure that the products they produce are safe and reliable. Here are some steps that can be taken to ensure quality control in pressure transmitter testing factories: 1. Establish Quality Standards: The first step in ensuring quality control is to establish quality standards. This should include setting specifications for the pressure transmitters, such as accuracy, repeatability, and response time. These standards should be clearly communicated to all employees and should be regularly monitored and updated as needed. 2. Implement Quality Assurance Procedures: Quality assurance procedures should be implemented to ensure that the pressure transmitters meet the established quality standards. This should include regular testing of the pressure transmitters to ensure that they are functioning properly and that they meet the established specifications.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

The Benefits of Automated Pressure Transmitter Testing in Manufacturing Facilities

Manufacturing facilities are complex and ever-evolving environments that require precise and reliable instrumentation to ensure the safety and efficiency of their operations. Pressure transmitters are a critical component of these systems, as they are responsible for measuring and controlling the pressure of various fluids and gases. As such, it is essential that these devices are regularly tested and calibrated to ensure their accuracy and reliability. In the past, pressure transmitter testing was a labor-intensive process that required manual calibration and testing of each device. This process was time-consuming and prone to human error, which could lead to inaccurate readings and costly downtime.

Fortunately, advances in technology have made automated pressure transmitter testing a viable option for many manufacturing facilities. Automated testing systems are designed to quickly and accurately test and calibrate pressure transmitters, eliminating the need for manual testing and calibration. This can save time and money, as well as reduce the risk of human error.

In addition to saving time and money, automated pressure transmitter testing also offers a number of other benefits. For example, automated systems can be programmed to test and calibrate multiple pressure transmitters simultaneously, allowing for faster and more efficient testing. Automated systems also provide detailed reports that can be used to identify any potential issues with the pressure transmitters, allowing for quick and easy troubleshooting.

Overall, automated pressure transmitter testing is a valuable tool for any manufacturing facility. It can save time and money, reduce the risk of human error, and provide detailed reports that can be used to identify and troubleshoot any potential issues. Automated testing systems are an invaluable asset for any facility looking to maximize efficiency and accuracy.

In the past, pressure transmitter testing was a labor-intensive process that required manual calibration and testing of each device. This process was time-consuming and prone to human error, which could lead to inaccurate readings and costly downtime.

Fortunately, advances in technology have made automated pressure transmitter testing a viable option for many manufacturing facilities. Automated testing systems are designed to quickly and accurately test and calibrate pressure transmitters, eliminating the need for manual testing and calibration. This can save time and money, as well as reduce the risk of human error.

In addition to saving time and money, automated pressure transmitter testing also offers a number of other benefits. For example, automated systems can be programmed to test and calibrate multiple pressure transmitters simultaneously, allowing for faster and more efficient testing. Automated systems also provide detailed reports that can be used to identify any potential issues with the pressure transmitters, allowing for quick and easy troubleshooting.

Overall, automated pressure transmitter testing is a valuable tool for any manufacturing facility. It can save time and money, reduce the risk of human error, and provide detailed reports that can be used to identify and troubleshoot any potential issues. Automated testing systems are an invaluable asset for any facility looking to maximize efficiency and accuracy.