Table of Contents

Understanding the Working Principle of Differential Pressure Sensors

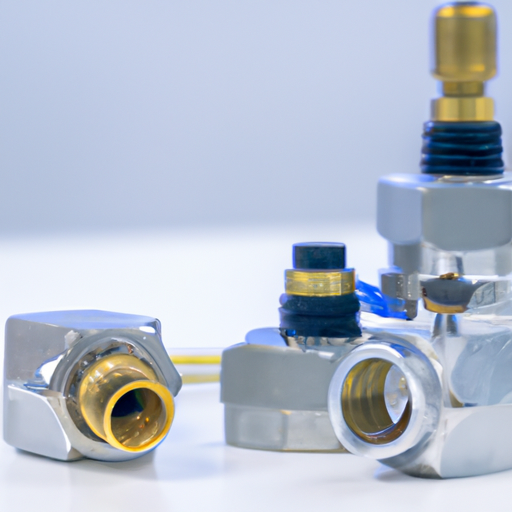

Differential pressure sensors are essential components in various industries, including automotive, aerospace, and HVAC systems. These sensors play a crucial role in measuring the difference in pressure between two points in a system. Understanding the working principle of these sensors is vital for ensuring accurate and reliable measurements. At its core, a differential pressure sensor consists of two pressure ports connected to a diaphragm or a sensing element. When pressure is applied to one port, it causes the diaphragm to deflect, creating a mechanical displacement. This displacement is then converted into an electrical signal by a transducer, such as a strain gauge or a capacitive sensor. One of the key factors that determine the performance of a differential pressure sensor is its sensitivity. Sensitivity refers to the change in output signal for a given change in pressure input. Higher sensitivity sensors can detect smaller pressure differentials, making them ideal for applications where precision is critical. Another important aspect of a differential pressure sensor is its range. The range of a sensor determines the maximum and minimum pressures it can measure accurately. It is essential to select a sensor with an appropriate range for the specific application to avoid saturation or damage to the sensor. In addition to sensitivity and range, the accuracy of a differential pressure sensor is also crucial. Accuracy refers to how closely the sensor’s output matches the actual pressure difference in the system. Factors such as temperature, humidity, and mechanical stress can affect the accuracy of a sensor, so it is essential to calibrate and maintain the sensor regularly. One of the most common types of differential pressure sensors is the strain gauge sensor. In this type of sensor, the diaphragm is connected to a set of strain gauges that change resistance when the diaphragm deflects. By measuring the change in resistance, the sensor can accurately determine the pressure difference between the two ports. Another type of differential pressure sensor is the capacitive sensor, which uses changes in capacitance to measure pressure differentials. In this type of sensor, the diaphragm acts as one plate of a capacitor, while the other plate is fixed. As the diaphragm deflects, the distance between the plates changes, causing a change in capacitance that can be measured and converted into a pressure reading. In conclusion, understanding the working principle of differential pressure sensors is essential for ensuring accurate and reliable measurements in various industrial applications. By considering factors such as sensitivity, range, and accuracy, as well as the type of sensor used, manufacturers can select the right sensor for their specific needs. With advancements in technology and manufacturing processes, China has become a leading manufacturer of high-quality differential pressure sensors that meet the demands of modern industries. By partnering with a reputable Chinese manufacturer, businesses can benefit from reliable and cost-effective sensors that help optimize their processes and improve overall efficiency.

Choosing a Reliable Manufacturer for Differential Pressure Sensors in China

Differential pressure sensors are crucial components in various industries, providing accurate measurements of pressure differences in systems. These sensors play a vital role in ensuring the efficiency and safety of processes in industries such as HVAC, automotive, aerospace, and medical equipment. When it comes to choosing a reliable manufacturer for these sensors, China has emerged as a leading hub for high-quality products at competitive prices.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |