Table of Contents

Exploring the Benefits of Working with a Pressure Transducer vs. Transmitter Supplier

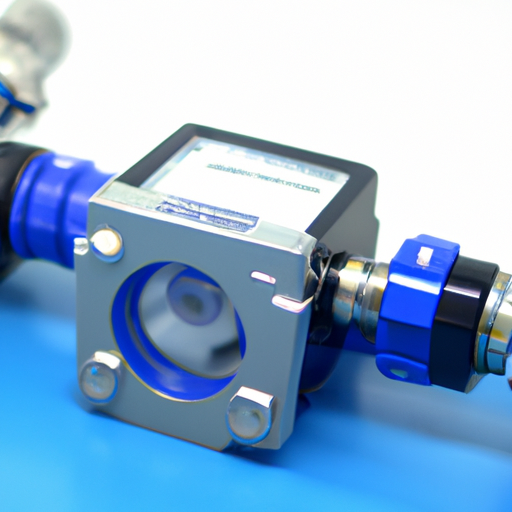

When it comes to selecting the right supplier for pressure transducers and transmitters, it is important to consider the benefits of working with a pressure transducer vs. transmitter supplier. Working with a pressure transducer supplier can provide a number of advantages over working with a transmitter supplier. Third, pressure transducers are typically more cost-effective than transmitters. This is because transducers are typically simpler in design and require fewer components than transmitters. This makes them less expensive to manufacture and purchase, which can be a major benefit for businesses looking to save money.

Finally, pressure transducers are typically easier to install and maintain than transmitters. This is because transducers are typically smaller and lighter than transmitters, making them easier to install and maintain. This can be a major advantage for businesses looking to reduce installation and maintenance costs.

Overall, working with a pressure transducer vs. transmitter supplier can provide a number of advantages. From increased accuracy and reliability to cost-effectiveness and ease of installation and maintenance, pressure transducers can be a great choice for businesses looking to get the most out of their pressure measurement systems.

Third, pressure transducers are typically more cost-effective than transmitters. This is because transducers are typically simpler in design and require fewer components than transmitters. This makes them less expensive to manufacture and purchase, which can be a major benefit for businesses looking to save money.

Finally, pressure transducers are typically easier to install and maintain than transmitters. This is because transducers are typically smaller and lighter than transmitters, making them easier to install and maintain. This can be a major advantage for businesses looking to reduce installation and maintenance costs.

Overall, working with a pressure transducer vs. transmitter supplier can provide a number of advantages. From increased accuracy and reliability to cost-effectiveness and ease of installation and maintenance, pressure transducers can be a great choice for businesses looking to get the most out of their pressure measurement systems.Comparing the Different Types of Pressure Transducers and Transmitters Available from Suppliers

When it comes to pressure transducers and transmitters, there are a variety of different types available from suppliers. Each type has its own unique features and benefits, so it is important to understand the differences between them in order to make an informed decision. One type of pressure transducer is the piezoelectric transducer. This type of transducer uses a piezoelectric material to convert mechanical energy into electrical energy. This type of transducer is often used in applications where high accuracy and repeatability are required. It is also relatively inexpensive and easy to install. Another type of pressure transducer is the capacitive transducer. This type of transducer uses a capacitor to measure pressure. It is often used in applications where a high degree of accuracy is required. It is also relatively inexpensive and easy to install. The third type of pressure transducer is the strain gauge transducer. This type of transducer uses a strain gauge to measure pressure. It is often used in applications where a high degree of accuracy is required. It is also relatively expensive and difficult to install.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |