Table of Contents

Understanding the Basics of Differential Pressure Sensors

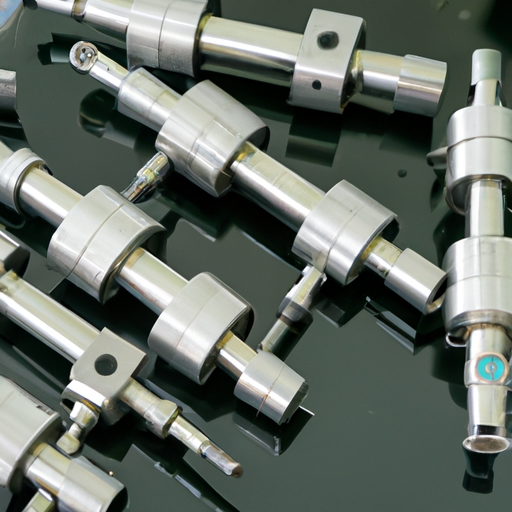

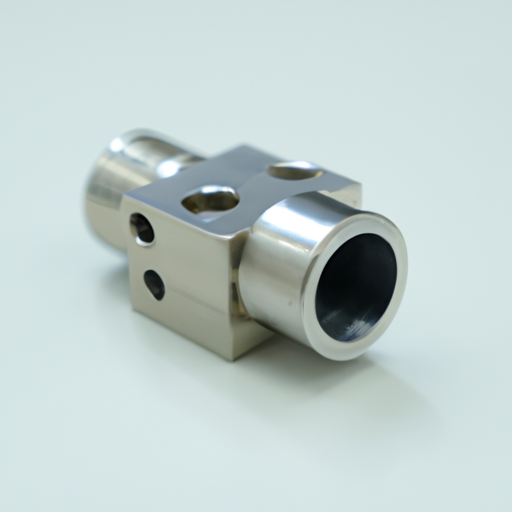

Differential pressure sensors are a crucial component in many industrial applications, providing accurate measurements of pressure differences between two points. Understanding the working principle of these sensors is essential for ensuring their proper functioning and reliable performance. In this article, we will delve into the basics of differential pressure sensors, exploring how they work and the key factors to consider when choosing a supplier for these critical devices. At its core, a differential pressure sensor measures the difference in pressure between two points in a system. This is achieved by comparing the pressure at one point with the pressure at another point, typically using a diaphragm or membrane that deflects in response to changes in pressure. As the pressure difference between the two points changes, the deflection of the diaphragm is converted into an electrical signal by a transducer, which can then be interpreted and displayed as a pressure reading. One of the key advantages of differential pressure sensors is their ability to provide accurate and reliable measurements in a wide range of applications. From monitoring fluid levels in tanks to measuring airflow in HVAC systems, these sensors play a crucial role in ensuring the efficiency and safety of industrial processes. By accurately measuring pressure differentials, differential pressure sensors can help detect leaks, blockages, or other issues that could impact the performance of a system. When choosing a supplier for differential pressure sensors, there are several factors to consider to ensure that you are getting a high-quality and reliable product. One of the most important considerations is the accuracy of the sensor, as even small deviations in pressure readings can have significant consequences in certain applications. Look for suppliers that offer sensors with high accuracy and precision, as well as the ability to calibrate and adjust the sensor as needed.

Top Suppliers of Differential Pressure Sensors for Industrial Applications

Differential pressure sensors are crucial components in various industrial applications, providing accurate measurements of pressure differences between two points. These sensors play a vital role in monitoring and controlling processes in industries such as HVAC, automotive, aerospace, and manufacturing. Understanding the working principle of differential pressure sensors is essential for selecting the right supplier to meet specific application requirements. The working principle of a differential pressure sensor is based on the measurement of the pressure difference between two pressure ports. These sensors typically consist of two pressure-sensitive diaphragms connected to a sensing element. When pressure is applied to one diaphragm, it deflects, causing a change in resistance or capacitance in the sensing element. The sensor then converts this change into an electrical signal that can be measured and interpreted. One of the top suppliers of differential pressure sensors for industrial applications is Honeywell. Honeywell offers a wide range of differential pressure sensors that are designed to meet the demanding requirements of various industries. These sensors are known for their high accuracy, reliability, and durability, making them ideal for critical applications where precise pressure measurements are essential.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |