Table of Contents

How Barometric Industrial Pressure Sensors are Revolutionizing the Chinese Manufacturing Industry

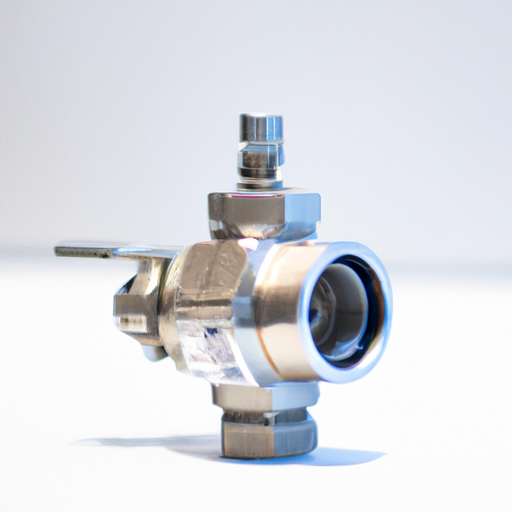

The Chinese manufacturing industry is undergoing a revolution, thanks to the introduction of barometric industrial pressure sensors. These sensors are revolutionizing the industry by providing manufacturers with a reliable and accurate way to measure and monitor pressure in their production processes. This technology is allowing manufacturers to optimize their production processes, resulting in improved efficiency, reduced costs, and increased profits. Barometric industrial pressure sensors are designed to measure and monitor pressure in a variety of industrial applications. These sensors are typically used in the production of chemicals, pharmaceuticals, and food products, as well as in the production of automotive components and other industrial products. The sensors are able to measure pressure in a variety of ranges, from low to high, and can be used to detect changes in pressure over time. This allows manufacturers to monitor their production processes and make adjustments as needed to ensure optimal performance.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

Exploring the Benefits of Barometric Industrial Pressure Sensors for Chinese Companies

The use of barometric industrial pressure sensors is becoming increasingly popular in China, as companies look to improve their production processes and reduce costs. This technology offers a range of benefits that can help Chinese companies to increase efficiency, reduce costs, and improve safety. In this article, we will explore the advantages of barometric industrial pressure sensors for Chinese companies. First, barometric industrial pressure sensors can help Chinese companies to improve their production processes. By accurately measuring the pressure of a process, companies can ensure that their production processes are running at optimal levels. This can help to reduce waste and improve the quality of the products they produce. Additionally, barometric industrial pressure sensors can help to reduce energy consumption, as they can be used to monitor and adjust the pressure of a process to ensure that it is running at the most efficient level. Second, barometric industrial pressure sensors can help Chinese companies to reduce costs. By accurately measuring the pressure of a process, companies can reduce the amount of energy they use, as well as the amount of raw materials they need to produce a product. This can help to reduce the overall cost of production, as well as the cost of the finished product. Additionally, barometric industrial pressure sensors can help to reduce the amount of time needed to complete a process, as they can be used to monitor and adjust the pressure of a process to ensure that it is running at the most efficient level.

Finally, barometric industrial pressure sensors can help to improve safety. By accurately measuring the pressure of a process, companies can ensure that their production processes are running at safe levels. This can help to reduce the risk of accidents and injuries, as well as the risk of damage to equipment and products. Additionally, barometric industrial pressure sensors can help to reduce the risk of environmental damage, as they can be used to monitor and adjust the pressure of a process to ensure that it is running at the most efficient level.

Second, barometric industrial pressure sensors can help Chinese companies to reduce costs. By accurately measuring the pressure of a process, companies can reduce the amount of energy they use, as well as the amount of raw materials they need to produce a product. This can help to reduce the overall cost of production, as well as the cost of the finished product. Additionally, barometric industrial pressure sensors can help to reduce the amount of time needed to complete a process, as they can be used to monitor and adjust the pressure of a process to ensure that it is running at the most efficient level.

Finally, barometric industrial pressure sensors can help to improve safety. By accurately measuring the pressure of a process, companies can ensure that their production processes are running at safe levels. This can help to reduce the risk of accidents and injuries, as well as the risk of damage to equipment and products. Additionally, barometric industrial pressure sensors can help to reduce the risk of environmental damage, as they can be used to monitor and adjust the pressure of a process to ensure that it is running at the most efficient level.