Table of Contents

How Differential Pressure Sensor Calibration Can Improve Your Processes

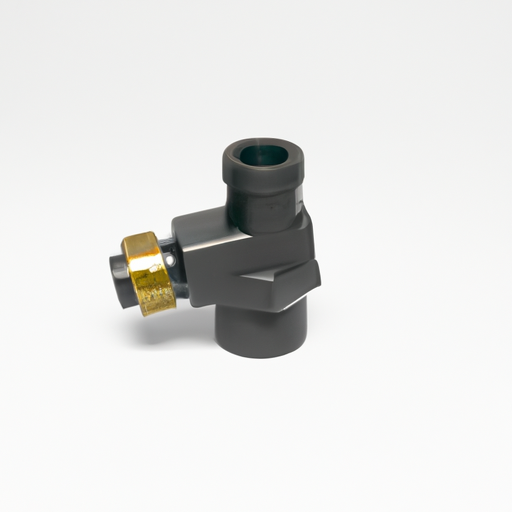

When it comes to improving your processes, there’s no better way to start than with differential pressure sensor calibration. This process ensures that your sensors are providing accurate readings, which can help you make better decisions and optimize your operations. Differential pressure sensors measure the difference in pressure between two points. This information is used to monitor and control a variety of processes, from air flow to liquid levels. But if the sensors are not properly calibrated, the readings can be inaccurate, leading to costly mistakes and inefficiencies. Calibrating your differential pressure sensors is a simple process that can have a big impact on your operations. By ensuring that your sensors are providing accurate readings, you can make better decisions and optimize your processes. For example, if you’re using differential pressure sensors to monitor air flow, you can use the accurate readings to adjust the flow rate and ensure that it’s at the optimal level. This can help you save energy and reduce costs.The Benefits of Working with a Professional Differential Pressure Sensor Calibration Company

When it comes to calibrating differential pressure sensors, it pays to work with a professional. A professional calibration company can provide you with the expertise and experience needed to ensure that your sensors are calibrated accurately and efficiently. Here are just a few of the benefits of working with a professional differential pressure sensor calibration company. First, a professional calibration company will have the right tools and equipment to get the job done right. They will have the latest technology and the most accurate instruments to ensure that your sensors are calibrated to the highest standards. This means that you can trust that your sensors will be calibrated correctly and that they will provide accurate readings.

Second, a professional calibration company will have the experience and knowledge to make sure that your sensors are calibrated correctly. They will be able to identify any potential problems and make sure that they are corrected before they become an issue. This means that you can trust that your sensors will be calibrated correctly and that they will provide accurate readings.

Third, a professional calibration company will be able to provide you with the best customer service. They will be able to answer any questions you may have and provide you with the support you need to ensure that your sensors are calibrated correctly. This means that you can trust that your sensors will be calibrated correctly and that they will provide accurate readings.

First, a professional calibration company will have the right tools and equipment to get the job done right. They will have the latest technology and the most accurate instruments to ensure that your sensors are calibrated to the highest standards. This means that you can trust that your sensors will be calibrated correctly and that they will provide accurate readings.

Second, a professional calibration company will have the experience and knowledge to make sure that your sensors are calibrated correctly. They will be able to identify any potential problems and make sure that they are corrected before they become an issue. This means that you can trust that your sensors will be calibrated correctly and that they will provide accurate readings.

Third, a professional calibration company will be able to provide you with the best customer service. They will be able to answer any questions you may have and provide you with the support you need to ensure that your sensors are calibrated correctly. This means that you can trust that your sensors will be calibrated correctly and that they will provide accurate readings.

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |