Table of Contents

How Differential Pressure Sensor Factories are Improving Quality Control

Differential pressure sensor factories are taking steps to improve quality control in order to ensure that their products meet the highest standards of accuracy and reliability. To achieve this, they are implementing a variety of measures, such as introducing more rigorous testing protocols, investing in advanced manufacturing equipment, and utilizing the latest quality control software. Finally, factories are utilizing the latest quality control software to ensure that all sensors meet the required specifications. This software is used to track the production process, detect any potential issues, and provide feedback to the factory on how to improve the process. This helps to ensure that all sensors are manufactured to the highest standards.

Finally, factories are utilizing the latest quality control software to ensure that all sensors meet the required specifications. This software is used to track the production process, detect any potential issues, and provide feedback to the factory on how to improve the process. This helps to ensure that all sensors are manufactured to the highest standards.

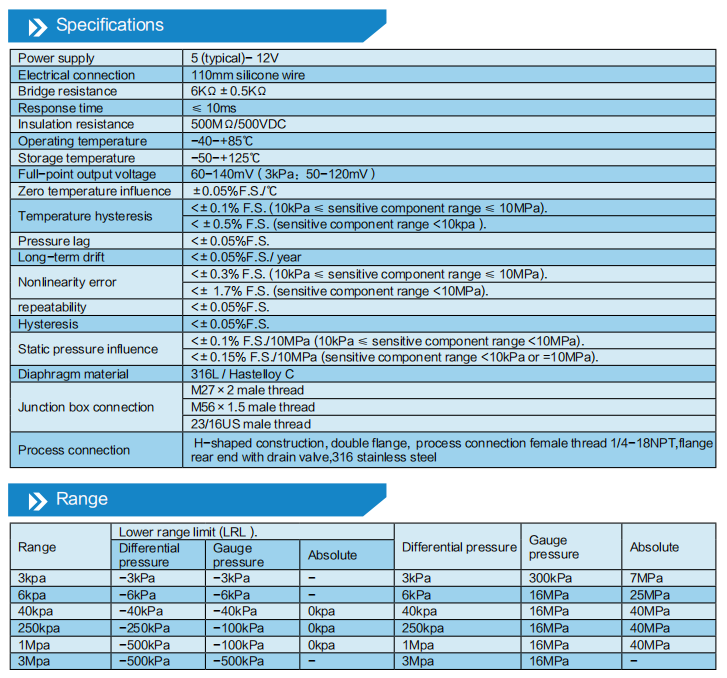

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |