Table of Contents

How Diffusion Silicon Pressure Transmitters are Revolutionizing the Chinese Manufacturing Industry

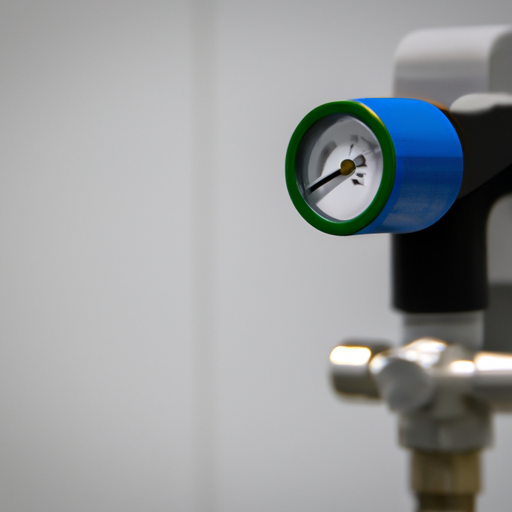

The Chinese manufacturing industry is undergoing a revolution, thanks to the introduction of diffusion silicon pressure transmitters. These devices are revolutionizing the way manufacturers measure and monitor pressure in their systems.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

Exploring the Benefits of High Grade Factory Diffusion Silicon Pressure Transmitters for Industrial Applications

When it comes to industrial applications, high grade factory diffusion silicon pressure transmitters are a must-have. These devices are designed to measure and monitor pressure in a variety of industrial settings, from manufacturing plants to oil and gas refineries. They are highly accurate and reliable, making them an ideal choice for any industrial application. The most important benefit of using high grade factory diffusion silicon pressure transmitters is their accuracy. These devices are designed to measure pressure with a high degree of accuracy, ensuring that the readings they provide are accurate and reliable. This accuracy is especially important in industrial settings, where even small variations in pressure can have a significant impact on the operation of the machinery. Another benefit of using high grade factory diffusion silicon pressure transmitters is their durability. These devices are designed to withstand extreme temperatures and pressures, making them ideal for use in harsh industrial environments. They are also designed to be resistant to corrosion, ensuring that they will last for many years without needing to be replaced. Finally, high grade factory diffusion silicon pressure transmitters are easy to install and maintain. They are designed to be user-friendly, allowing for quick and easy installation and maintenance. This makes them ideal for use in industrial settings, where time is of the essence.

High grade factory diffusion silicon pressure transmitters are an invaluable tool for any industrial application. They are highly accurate, reliable, and durable, making them an ideal choice for any industrial setting. They are also easy to install and maintain, ensuring that they will provide accurate readings for many years to come. If you are looking for a reliable and accurate pressure transmitter for your industrial application, then high grade factory diffusion silicon pressure transmitters are the perfect choice.

Finally, high grade factory diffusion silicon pressure transmitters are easy to install and maintain. They are designed to be user-friendly, allowing for quick and easy installation and maintenance. This makes them ideal for use in industrial settings, where time is of the essence.

High grade factory diffusion silicon pressure transmitters are an invaluable tool for any industrial application. They are highly accurate, reliable, and durable, making them an ideal choice for any industrial setting. They are also easy to install and maintain, ensuring that they will provide accurate readings for many years to come. If you are looking for a reliable and accurate pressure transmitter for your industrial application, then high grade factory diffusion silicon pressure transmitters are the perfect choice.