Table of Contents

How Intelligent Valve Technology is Revolutionizing Flow Control in Manufacturing

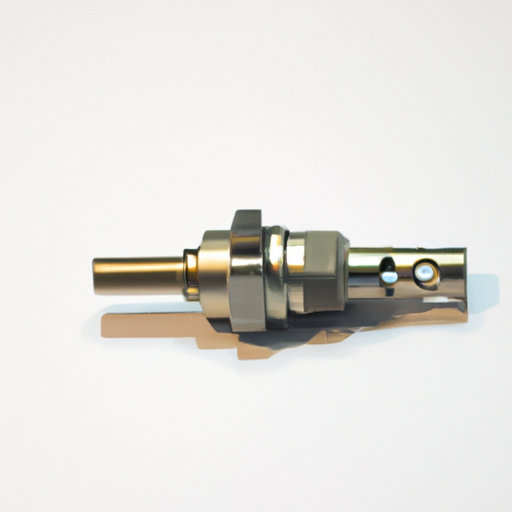

Intelligent valve technology is revolutionizing flow control in manufacturing. This technology uses sensors and actuators to monitor and control the flow of liquids and gases in industrial processes. It is a major advancement in the field of flow control, as it allows for more precise and efficient control of the flow of materials. The intelligent valve technology works by using sensors to detect changes in pressure, temperature, and other parameters. The sensors then send signals to the actuators, which adjust the flow of the material accordingly. This allows for more precise control of the flow, as well as improved safety and efficiency.| function | pressure/differential pressure/temperature/temperature difference/energy control |

| Rated pressure of valve | 16Bar |

| Applicable fluid of valve | cold/hot water |

| Working temperature of intelligent valve | -20℃ -80℃ |

| Protection class of actuator | IP67 |

| Intelligent valve digital communication | Modbus485/M-BUS |

| Intelligent valve analog communication | Die-casting aluminum |

| Main material of actuator | 24VDC/3A |

| function | temperature/temperature difference/energy control |

| Rated pressure of valve | 16Bar |

| Applicable fluid of valve | cold/hot water |

| Working temperature of intelligent valve | -20℃ -80℃ |

| Protection class of actuator | IP67 |

| Intelligent valve digital communication | Modbus485/M-BUS |

| Intelligent valve analog communication | Die-casting aluminum |

| Main material of actuator | 24VDC/3A |

| Wireless communication of intelligent valve | NB-IOt/ROLA/GpRS/4G |

| Intelligent valve analog communication | 4-20mA/0-10V |

| Intelligent valve digital communication | Modbus485/M-BUS |

| Control accuracy of intelligent valve | 1% |

| Opening accuracy of intelligent valve | 1% |

Exploring the Benefits of Automated Flow Control with Intelligent Valves in Industrial Settings

The use of automated flow control with intelligent valves in industrial settings can provide a number of benefits. By automating the flow of liquids and gases, industrial processes can be made more efficient, reliable, and cost-effective.| Wireless communication of intelligent valve | NB-IOt/ROLA/GpRS/4G |

| Intelligent valve analog communication | 4-20mA/0-10V |

| Intelligent valve digital communication | Modbus485/M-BUS |

| Control accuracy of intelligent valve | 1% |

| Opening accuracy of intelligent valve | 1% |

| Ambient humidity: | 5~95% |

| Differential pressure range: | 16Bar |

| Interface thread: | Internal thread G1/4 |

| Shell material: | alufer |

| Pressure range: | 0-1.6Mpa |

Finally, automated flow control can help to reduce costs. By eliminating the need for manual labor, intelligent valves can help to reduce labor costs and increase productivity. Additionally, intelligent valves can help to reduce energy costs by ensuring that the desired flow rate is maintained.

Finally, automated flow control can help to reduce costs. By eliminating the need for manual labor, intelligent valves can help to reduce labor costs and increase productivity. Additionally, intelligent valves can help to reduce energy costs by ensuring that the desired flow rate is maintained.

Overall, automated flow control with intelligent valves can provide a number of benefits in industrial settings. By improving accuracy, increasing safety, and reducing costs, intelligent valves can help to make industrial processes more efficient and cost-effective.

Overall, automated flow control with intelligent valves can provide a number of benefits in industrial settings. By improving accuracy, increasing safety, and reducing costs, intelligent valves can help to make industrial processes more efficient and cost-effective.