Table of Contents

How Pressure Sensors are Used in Industrial Automation

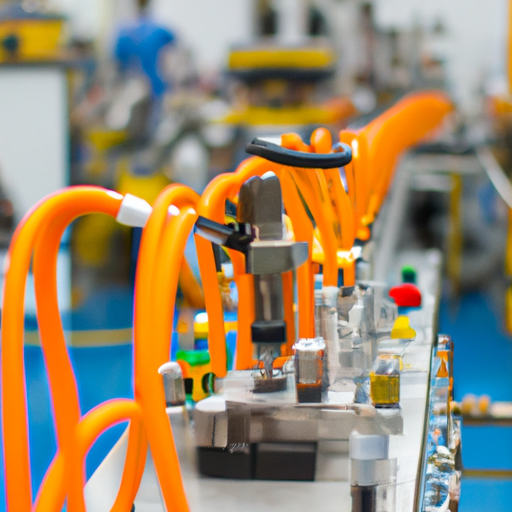

Pressure sensors are widely used in industrial automation for a variety of applications. They are used to measure the pressure of liquids, gases, and vapors in a variety of industrial processes. Pressure sensors are used to monitor and control the pressure of a system, ensuring that it remains within a safe range. They are also used to detect changes in pressure, allowing for quick and accurate responses to changes in the system. In industrial automation, pressure sensors are used to measure the pressure of liquids, gases, and vapors in a variety of processes. They are used to monitor and control the pressure of a system, ensuring that it remains within a safe range. Pressure sensors are also used to detect changes in pressure, allowing for quick and accurate responses to changes in the system. This helps to ensure that the system is operating safely and efficiently. Pressure sensors are also used to measure the flow rate of liquids, gases, and vapors. This is important for controlling the flow rate of a system, ensuring that it remains within a safe range. Pressure sensors are also used to detect changes in flow rate, allowing for quick and accurate responses to changes in the system.The Benefits of Using Pressure Sensors in Industrial Applications

Pressure sensors are widely used in industrial applications due to their ability to accurately measure pressure in a variety of environments. Pressure sensors are used to measure the pressure of liquids, gases, and vapors, and can be used in a variety of applications, including process control, safety monitoring, and environmental monitoring. Pressure sensors offer a number of benefits to industrial applications, including improved accuracy, increased safety, and cost savings.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

Pressure sensors also offer increased safety in industrial applications. Pressure sensors can be used to monitor pressure levels in hazardous environments, such as those containing flammable or explosive gases. By monitoring pressure levels, pressure sensors can help to prevent dangerous situations from occurring. Pressure sensors can also be used to detect leaks in pipes and other systems, which can help to prevent costly damage and downtime.

Finally, pressure sensors can help to reduce costs in industrial applications. Pressure sensors can be used to monitor pressure levels in systems, which can help to reduce energy consumption. By monitoring pressure levels, pressure sensors can help to ensure that systems are running at the most efficient pressure levels, which can help to reduce energy costs. Pressure sensors can also help to reduce maintenance costs, as they can detect problems before they become serious and require costly repairs.

Overall, pressure sensors offer a number of benefits to industrial applications. Pressure sensors offer improved accuracy, increased safety, and cost savings, which can help to improve the efficiency and productivity of industrial processes.

Pressure sensors also offer increased safety in industrial applications. Pressure sensors can be used to monitor pressure levels in hazardous environments, such as those containing flammable or explosive gases. By monitoring pressure levels, pressure sensors can help to prevent dangerous situations from occurring. Pressure sensors can also be used to detect leaks in pipes and other systems, which can help to prevent costly damage and downtime.

Finally, pressure sensors can help to reduce costs in industrial applications. Pressure sensors can be used to monitor pressure levels in systems, which can help to reduce energy consumption. By monitoring pressure levels, pressure sensors can help to ensure that systems are running at the most efficient pressure levels, which can help to reduce energy costs. Pressure sensors can also help to reduce maintenance costs, as they can detect problems before they become serious and require costly repairs.

Overall, pressure sensors offer a number of benefits to industrial applications. Pressure sensors offer improved accuracy, increased safety, and cost savings, which can help to improve the efficiency and productivity of industrial processes.