Table of Contents

Exploring the Benefits of Pressure Sensor Array Technology in Chinese Manufacturing

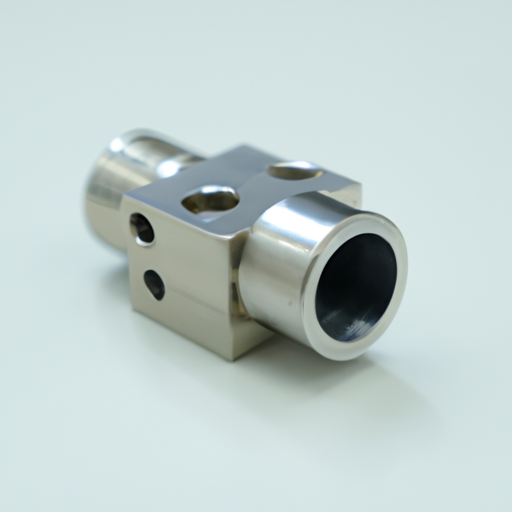

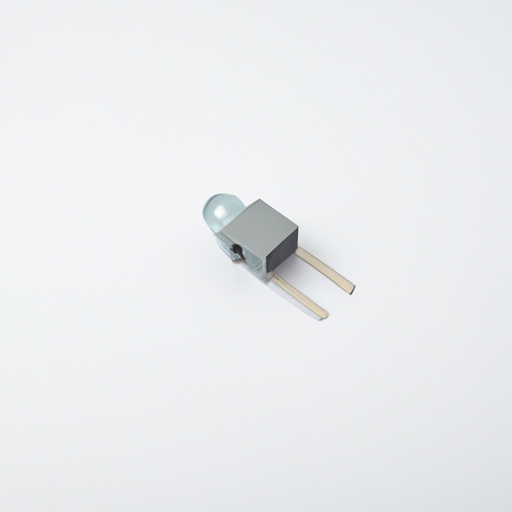

The Chinese manufacturing industry is rapidly evolving, and pressure sensor array technology is playing an increasingly important role in this transformation. Pressure sensor array technology is a type of sensing technology that uses multiple pressure sensors to measure the pressure of a given object or environment. This technology has the potential to revolutionize the Chinese manufacturing industry by providing manufacturers with a more accurate and efficient way to measure and monitor pressure.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

How Pressure Sensor Array Technology is Revolutionizing Quality Control in Chinese Factories

The Chinese manufacturing industry is undergoing a revolution in quality control, thanks to the introduction of pressure sensor array technology. This technology is transforming the way factories monitor and control the quality of their products, allowing them to produce goods of a higher standard than ever before. Pressure sensor array technology works by measuring the pressure applied to a surface. This data is then used to detect any irregularities in the product, such as unevenness or defects. By using this technology, factories can quickly identify any issues with their products and take corrective action before they reach the customer. This helps to ensure that only the highest quality products are produced. The technology is also helping to reduce costs associated with quality control. By detecting issues early on, factories can avoid costly rework and scrap costs. Additionally, the technology can be used to monitor the performance of machines, allowing factories to identify any issues with their equipment before they become a problem. This helps to reduce downtime and improve efficiency.

Finally, pressure sensor array technology is helping to improve safety in Chinese factories. By monitoring the pressure applied to a surface, factories can detect any potential hazards before they become a problem. This helps to reduce the risk of accidents and injuries in the workplace.

Overall, pressure sensor array technology is revolutionizing quality control in Chinese factories. By allowing factories to quickly identify any issues with their products, reduce costs associated with quality control, and improve safety in the workplace, this technology is helping to ensure that only the highest quality products are produced.

The technology is also helping to reduce costs associated with quality control. By detecting issues early on, factories can avoid costly rework and scrap costs. Additionally, the technology can be used to monitor the performance of machines, allowing factories to identify any issues with their equipment before they become a problem. This helps to reduce downtime and improve efficiency.

Finally, pressure sensor array technology is helping to improve safety in Chinese factories. By monitoring the pressure applied to a surface, factories can detect any potential hazards before they become a problem. This helps to reduce the risk of accidents and injuries in the workplace.

Overall, pressure sensor array technology is revolutionizing quality control in Chinese factories. By allowing factories to quickly identify any issues with their products, reduce costs associated with quality control, and improve safety in the workplace, this technology is helping to ensure that only the highest quality products are produced.