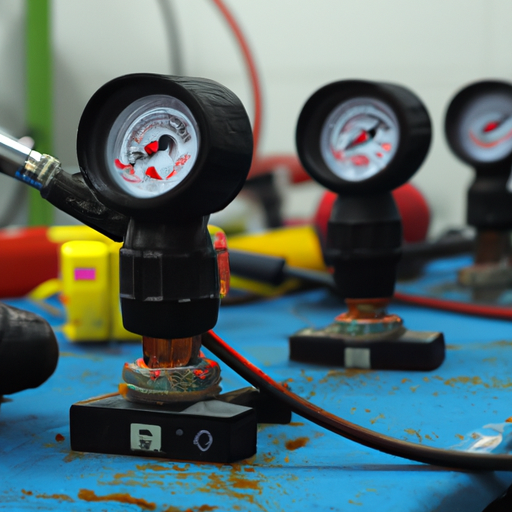

L’importance des capteurs de pression dans les applications industrielles

Milieu de mesure

| Gaz, vapeurs, liquides | Inexactitude |

| 0,075% | stabilité |

| 0,1%/3 ans | L’un des principaux avantages des capteurs de pression est leur capacité à fournir des données en temps réel. Cela permet aux opérateurs de surveiller les niveaux de pression en continu et de détecter toute anomalie ou écart par rapport à la plage souhaitée. Ce faisant, les problèmes potentiels peuvent être identifiés et résolus rapidement, minimisant ainsi le risque de dommages ou de temps d’arrêt de l’équipement. Par exemple, dans une usine de fabrication, des capteurs de pression peuvent être utilisés pour surveiller la pression dans un système hydraulique, garantissant ainsi qu’elle reste dans la plage spécifiée. Si la pression dépasse la limite, une alarme peut être déclenchée, avertissant les opérateurs de prendre des mesures immédiates. |

When choosing a pressure sensor supplier in China, it is important to consider factors such as the reputation of the factory, the quality of their products, and their ability to provide customized solutions. High-grade pressure sensors should be made from durable materials that can withstand harsh industrial environments and provide accurate and reliable measurements. Additionally, the supplier should have a strong technical support team that can assist with installation, calibration, and troubleshooting.In conclusion, pressure sensors are indispensable in industrial applications, providing real-time data that is crucial for maintaining optimal performance and ensuring safety. These sensors enable operators to monitor and control pressure levels, detect abnormalities, and take necessary actions to prevent equipment failure and enhance productivity. China has become a prominent player in the pressure sensor industry, offering high-grade products that meet the stringent requirements of industrial applications. When choosing a pressure sensor supplier, it is important to consider factors such as reputation, product quality, and technical support to ensure the best possible solution for your specific needs.

When choosing a pressure sensor supplier in China, it is important to consider factors such as the reputation of the factory, the quality of their products, and their ability to provide customized solutions. High-grade pressure sensors should be made from durable materials that can withstand harsh industrial environments and provide accurate and reliable measurements. Additionally, the supplier should have a strong technical support team that can assist with installation, calibration, and troubleshooting.In conclusion, pressure sensors are indispensable in industrial applications, providing real-time data that is crucial for maintaining optimal performance and ensuring safety. These sensors enable operators to monitor and control pressure levels, detect abnormalities, and take necessary actions to prevent equipment failure and enhance productivity. China has become a prominent player in the pressure sensor industry, offering high-grade products that meet the stringent requirements of industrial applications. When choosing a pressure sensor supplier, it is important to consider factors such as reputation, product quality, and technical support to ensure the best possible solution for your specific needs.