Table of Contents

Differential Pressure Sensor Technology: How Chinese Factories are Revolutionizing the Industry

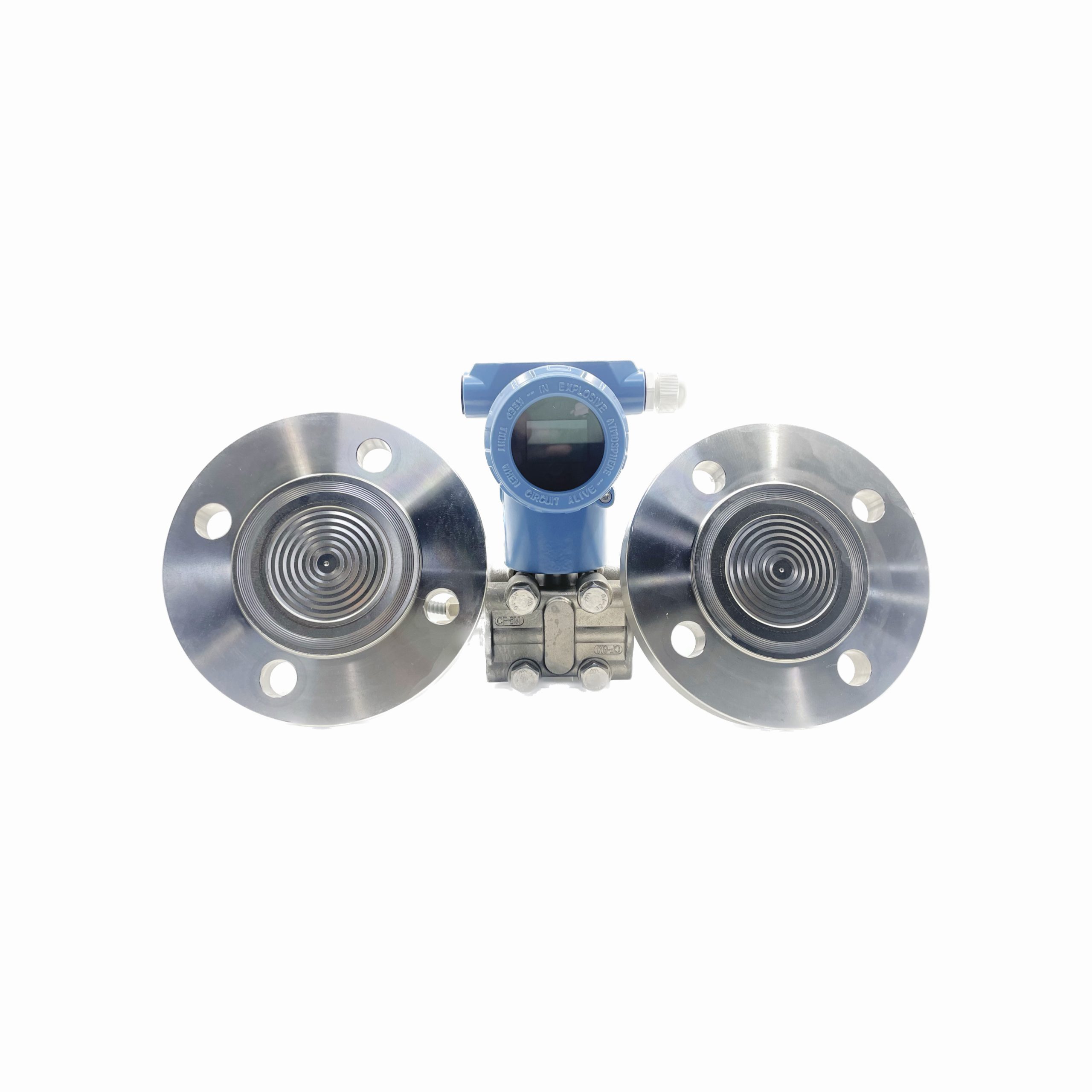

The Chinese manufacturing industry is revolutionizing the differential pressure sensor technology industry. By utilizing advanced technologies and innovative production methods, Chinese factories are producing high-quality, cost-effective sensors that are quickly becoming the industry standard. In comparison to traditional differential pressure sensor technology, Chinese factories are able to produce sensors with greater accuracy and precision. This is due to their use of advanced technologies such as laser cutting and 3D printing. These technologies allow for more precise measurements and tighter tolerances, resulting in sensors that are more reliable and accurate.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

In addition to cost savings, Chinese factories are also able to produce sensors with a much shorter lead time. This is due to their use of advanced technologies such as rapid prototyping and automated assembly. By utilizing these technologies, Chinese factories are able to produce sensors in a fraction of the time it would take to produce them using traditional methods.

Finally, Chinese factories are able to produce sensors with a much higher level of quality control. This is due to their use of advanced quality control systems and rigorous testing procedures. By utilizing these methods, Chinese factories are able to ensure that their sensors meet the highest standards of quality and reliability.

Overall, Chinese factories are revolutionizing the differential pressure sensor technology industry. By utilizing advanced technologies and innovative production methods, Chinese factories are producing high-quality, cost-effective sensors that are quickly becoming the industry standard.

In addition to cost savings, Chinese factories are also able to produce sensors with a much shorter lead time. This is due to their use of advanced technologies such as rapid prototyping and automated assembly. By utilizing these technologies, Chinese factories are able to produce sensors in a fraction of the time it would take to produce them using traditional methods.

Finally, Chinese factories are able to produce sensors with a much higher level of quality control. This is due to their use of advanced quality control systems and rigorous testing procedures. By utilizing these methods, Chinese factories are able to ensure that their sensors meet the highest standards of quality and reliability.

Overall, Chinese factories are revolutionizing the differential pressure sensor technology industry. By utilizing advanced technologies and innovative production methods, Chinese factories are producing high-quality, cost-effective sensors that are quickly becoming the industry standard.