Table of Contents

How Differential Pressure Sensors are Used in HVAC Systems to Improve Efficiency

HVAC systems are essential for providing comfortable temperatures in homes and businesses. To ensure that these systems are running efficiently, differential pressure sensors are used to measure the pressure difference between two points in the system. This helps to identify any blockages or restrictions that could be causing the system to run inefficiently. Differential pressure sensors measure the difference in pressure between two points in the system. This can be used to detect any blockages or restrictions that could be causing the system to run inefficiently. For example, if the pressure difference between two points is too high, it could indicate that there is a blockage in the system. By detecting these blockages, the system can be adjusted to ensure that it is running as efficiently as possible. Differential pressure sensors can also be used to measure the air flow in the system. This helps to identify any areas where the air flow is restricted, which can lead to inefficient operation. By measuring the air flow, the system can be adjusted to ensure that it is running as efficiently as possible.| Measuring medium | Gases, vapours, liquids |

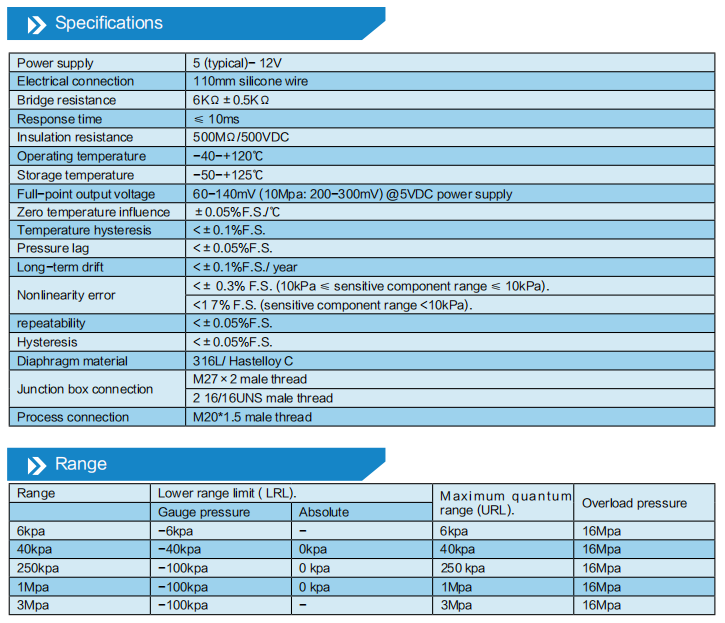

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

The Benefits of Purchasing Differential Pressure Sensors from Chinese Manufacturers

When it comes to purchasing differential pressure sensors, Chinese manufacturers offer a number of advantages. Differential pressure sensors are used in a variety of industries, including HVAC, medical, and industrial, and Chinese manufacturers offer a wide range of products to meet the needs of these industries. One of the main benefits of purchasing differential pressure sensors from Chinese manufacturers is cost. Chinese manufacturers are able to offer competitive prices due to their low overhead costs and access to a large pool of skilled labor. This means that customers can get the same quality product at a fraction of the cost of purchasing from a domestic manufacturer.

Another benefit of purchasing differential pressure sensors from Chinese manufacturers is the wide range of products available. Chinese manufacturers offer a variety of different types of sensors, including digital, analog, and wireless. This means that customers can find the right sensor for their specific application. Additionally, Chinese manufacturers often offer customization options, allowing customers to tailor their sensors to their exact needs.

Finally, Chinese manufacturers are known for their high-quality products. Chinese manufacturers use the latest technology and materials to ensure that their products are reliable and accurate. This means that customers can trust that their sensors will perform as expected and provide accurate readings.

Overall, purchasing differential pressure sensors from Chinese manufacturers offers a number of advantages. Customers can save money, find the right product for their application, and trust that their sensors will be reliable and accurate. For these reasons, Chinese manufacturers are an excellent choice for purchasing differential pressure sensors.

One of the main benefits of purchasing differential pressure sensors from Chinese manufacturers is cost. Chinese manufacturers are able to offer competitive prices due to their low overhead costs and access to a large pool of skilled labor. This means that customers can get the same quality product at a fraction of the cost of purchasing from a domestic manufacturer.

Another benefit of purchasing differential pressure sensors from Chinese manufacturers is the wide range of products available. Chinese manufacturers offer a variety of different types of sensors, including digital, analog, and wireless. This means that customers can find the right sensor for their specific application. Additionally, Chinese manufacturers often offer customization options, allowing customers to tailor their sensors to their exact needs.

Finally, Chinese manufacturers are known for their high-quality products. Chinese manufacturers use the latest technology and materials to ensure that their products are reliable and accurate. This means that customers can trust that their sensors will perform as expected and provide accurate readings.

Overall, purchasing differential pressure sensors from Chinese manufacturers offers a number of advantages. Customers can save money, find the right product for their application, and trust that their sensors will be reliable and accurate. For these reasons, Chinese manufacturers are an excellent choice for purchasing differential pressure sensors.