Table of Contents

How Industrial Pressure Sensors are Used in Automation and Manufacturing

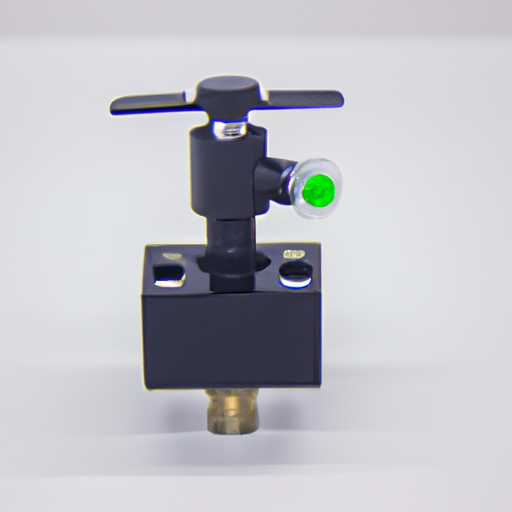

Industrial pressure sensors are an essential component of automation and manufacturing processes. They are used to measure the pressure of liquids, gases, and other substances in a variety of industrial applications. Pressure sensors are used to monitor and control the pressure of a system, ensuring that it remains within a safe range. This helps to ensure the safety of workers and the efficiency of the production process. In automation and manufacturing, pressure sensors are used to measure the pressure of liquids, gases, and other substances. This information is then used to control the flow of the substance, ensuring that it is within the desired range. Pressure sensors can also be used to detect changes in pressure, allowing for quick and accurate adjustments to be made. This helps to ensure that the system remains safe and efficient.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

The Benefits of Investing in Industrial Pressure Sensors for Your Factory

Investing in industrial pressure sensors for your factory can be a great way to improve the efficiency and safety of your operations. Pressure sensors are used to measure the pressure of liquids and gases in a variety of industrial applications, and they can provide valuable information about the performance of your equipment. Here are some of the key benefits of investing in industrial pressure sensors for your factory. First, pressure sensors can help you monitor the performance of your equipment. By measuring the pressure of liquids and gases, you can get an accurate picture of how your equipment is performing. This can help you identify any potential problems before they become serious, allowing you to take corrective action quickly. Second, pressure sensors can help you improve the safety of your operations. By monitoring the pressure of liquids and gases, you can ensure that your equipment is operating within safe parameters. This can help you avoid accidents and injuries, as well as reduce the risk of costly repairs or replacements. Third, pressure sensors can help you save money. By monitoring the pressure of liquids and gases, you can identify any potential problems before they become serious, allowing you to take corrective action quickly. This can help you avoid costly repairs or replacements, as well as reduce the amount of energy you use. Investing in industrial pressure sensors for your factory can be a great way to improve the efficiency and safety of your operations. By monitoring the pressure of liquids and gases, you can get an accurate picture of how your equipment is performing, identify any potential problems before they become serious, and save money on energy costs. With all these benefits, it’s easy to see why investing in industrial pressure sensors is a smart move for any factory.

Investing in industrial pressure sensors for your factory can be a great way to improve the efficiency and safety of your operations. By monitoring the pressure of liquids and gases, you can get an accurate picture of how your equipment is performing, identify any potential problems before they become serious, and save money on energy costs. With all these benefits, it’s easy to see why investing in industrial pressure sensors is a smart move for any factory.