Table of Contents

How to Properly Install a Pressure Transmitter with a 2-Wire Connection

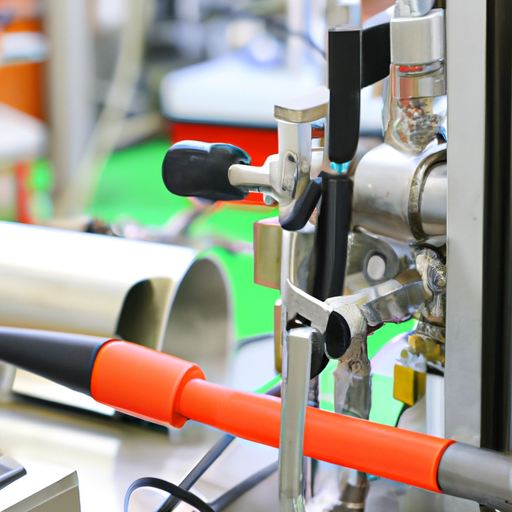

Installing a pressure transmitter with a two-wire connection is a relatively simple process that can be completed in a few easy steps. Here’s how to do it: 1. Start by mounting the pressure transmitter to the desired location. Make sure the transmitter is securely fastened and that the pressure port is properly aligned. 2. Connect the two wires to the transmitter. Make sure the wires are securely connected and that the polarity is correct. 3. Connect the other end of the wires to the power source. Make sure the power source is compatible with the transmitter and that the voltage is correct. 4. Once the wiring is complete, turn on the power source and check the transmitter’s readings. Make sure the readings are accurate and that the transmitter is functioning properly. 5. Finally, calibrate the transmitter if necessary. This will ensure that the readings are accurate and that the transmitter is working correctly. Following these steps will ensure that your pressure transmitter is properly installed and functioning correctly. With a two-wire connection, you can easily monitor pressure levels and make sure your system is running smoothly.The Benefits of Using a Pressure Transmitter with a 2-Wire Connection for Industrial Applications

A pressure transmitter with a 2-wire connection is an ideal choice for industrial applications. This type of transmitter offers a number of benefits that make it a great choice for industrial applications. First, a pressure transmitter with a 2-wire connection is easy to install and maintain. This type of transmitter requires only two wires for connection, making it much simpler to install than other types of transmitters. Additionally, the two-wire connection makes it easier to troubleshoot any issues that may arise. Second, a pressure transmitter with a 2-wire connection is more reliable than other types of transmitters. This type of transmitter is designed to be more resistant to interference and noise, which can cause inaccurate readings. Additionally, the two-wire connection ensures that the transmitter is always connected to the power source, which helps to ensure that readings are always accurate.

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |