Table of Contents

How Diffusion Silicon Pressure Transmitters are Used in Industrial Manufacturing

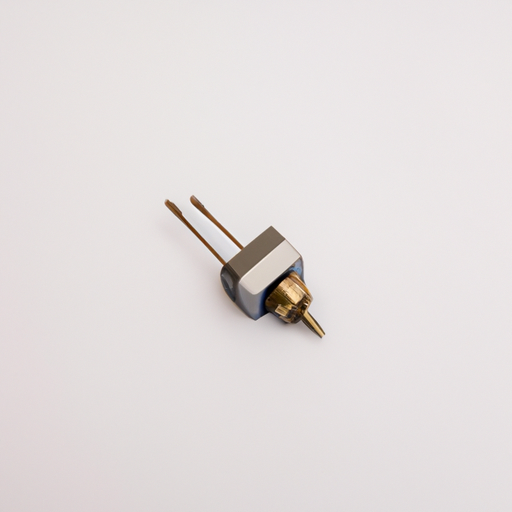

Diffusion silicon pressure transmitters are used in industrial manufacturing to measure and monitor pressure levels in a variety of applications. These devices are used to measure the pressure of liquids, gases, and vapors in a variety of industrial processes. They are also used to measure the pressure of steam, air, and other fluids. The diffusion silicon pressure transmitters are designed to be highly accurate and reliable. They are able to measure pressure levels with a high degree of accuracy and repeatability. This makes them ideal for use in industrial manufacturing processes where precise measurements are required. The diffusion silicon pressure transmitters are also used to monitor pressure levels in safety-critical applications. They can be used to detect changes in pressure levels that could indicate a potential safety hazard. This helps to ensure that the manufacturing process is running safely and efficiently. The diffusion silicon pressure transmitters are also used to control the flow of fluids in industrial processes. They can be used to regulate the flow of liquids, gases, and vapors in order to maintain a safe and efficient manufacturing process. Overall, diffusion silicon pressure transmitters are an essential part of industrial manufacturing processes. They are used to measure and monitor pressure levels, detect potential safety hazards, and regulate the flow of fluids. They are highly accurate and reliable, making them an invaluable tool for industrial manufacturing.The Benefits of Automating Pressure Measurement with Diffusion Silicon Pressure Transmitters

Automating pressure measurement with diffusion silicon pressure transmitters offers a number of benefits. These transmitters are reliable, accurate, and easy to install and maintain. First, diffusion silicon pressure transmitters are reliable. They are designed to withstand extreme temperatures, pressure, and vibration, making them ideal for use in harsh industrial environments. They also have a long lifespan, so you can count on them to provide accurate readings for years to come.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |