Table of Contents

How Pressure Transducers Help Gas Companies Monitor and Control Gas Flow

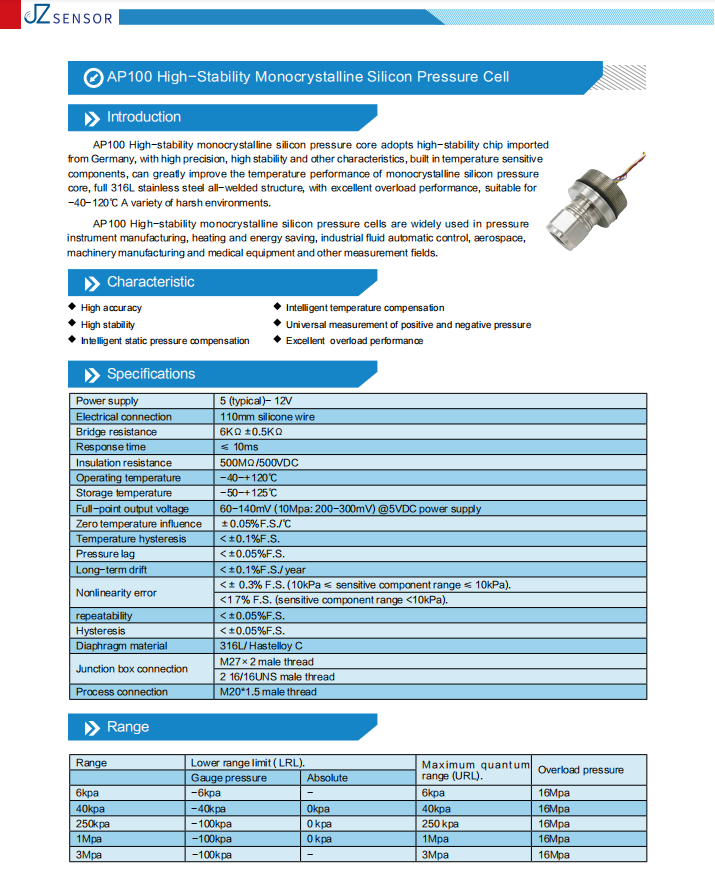

Gas companies have a lot of responsibility when it comes to monitoring and controlling the flow of gas. It’s important to make sure that the gas is flowing safely and efficiently, and that it’s not being wasted or misused. That’s why pressure transducers are so important for gas companies. Pressure transducers are devices that measure the pressure of a gas or liquid. They’re used to monitor the flow of gas and make sure that it’s flowing at the right rate. They can also be used to detect any changes in pressure, which can indicate a problem with the flow. The pressure transducer works by measuring the pressure of the gas or liquid and then sending a signal to a controller. The controller then uses this signal to adjust the flow of the gas. This helps to ensure that the gas is flowing at the right rate and that it’s not being wasted or misused. The pressure transducer also helps to detect any changes in pressure, which can indicate a problem with the flow. This helps to prevent any accidents or damage that could be caused by a sudden change in pressure.

Overall, pressure transducers are an important tool for gas companies. They help to monitor and control the flow of gas, ensuring that it’s flowing safely and efficiently. They also help to detect any changes in pressure, which can indicate a problem with the flow. This helps to prevent any accidents or damage that could be caused by a sudden change in pressure.

The pressure transducer also helps to detect any changes in pressure, which can indicate a problem with the flow. This helps to prevent any accidents or damage that could be caused by a sudden change in pressure.

Overall, pressure transducers are an important tool for gas companies. They help to monitor and control the flow of gas, ensuring that it’s flowing safely and efficiently. They also help to detect any changes in pressure, which can indicate a problem with the flow. This helps to prevent any accidents or damage that could be caused by a sudden change in pressure.The Benefits of Automated Pressure Transducer Monitoring for Gas Companies

If you’re a gas company, you know that pressure transducers are essential for monitoring and controlling the pressure of your gas lines. But manually monitoring these transducers can be time-consuming and labor-intensive. That’s why automated pressure transducer monitoring is such a great option for gas companies. Here are some of the benefits of automated pressure transducer monitoring: 1. Increased Efficiency: Automated pressure transducer monitoring can help you save time and money by eliminating the need for manual monitoring. With automated monitoring, you can quickly and easily monitor your pressure transducers from a single location, allowing you to quickly identify any issues and take corrective action.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |