Table of Contents

How Pressure Sensors are Revolutionizing Water Level Measurement for Manufacturers

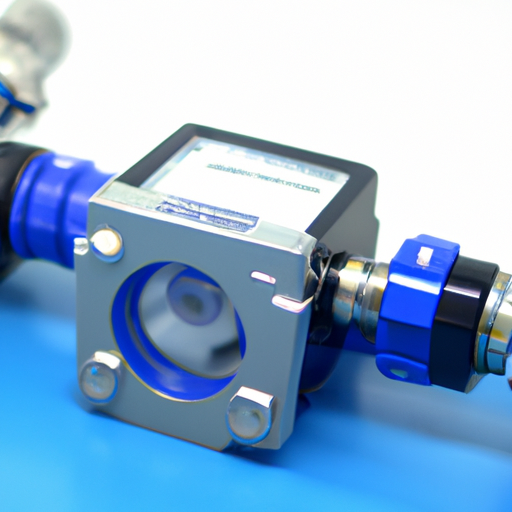

Manufacturers are increasingly turning to pressure sensors to revolutionize the way they measure water levels. Pressure sensors are highly accurate, reliable, and cost-effective, making them an ideal choice for manufacturers who need to monitor water levels in their operations. Pressure sensors measure the pressure of a liquid or gas, and can be used to accurately measure the level of water in a tank or other container. Pressure sensors are able to measure the pressure of the water in the tank, and then convert that pressure into a digital signal that can be read by a computer or other device. This digital signal can then be used to accurately measure the water level in the tank. The accuracy of pressure sensors makes them ideal for manufacturers who need to monitor water levels in their operations. Pressure sensors are able to measure the water level in a tank with an accuracy of up to 0.1%, which is far more accurate than traditional methods of measuring water levels. This accuracy ensures that manufacturers can accurately monitor the water levels in their tanks, and can take action if the levels become too high or too low.

The reliability of pressure sensors also makes them an ideal choice for manufacturers. Pressure sensors are designed to be highly durable and reliable, and can withstand extreme temperatures and pressures. This ensures that manufacturers can rely on their pressure sensors to accurately measure the water levels in their tanks, even in the most extreme conditions.

Finally, pressure sensors are also cost-effective. Pressure sensors are relatively inexpensive, and can be easily installed in a tank or other container. This makes them an ideal choice for manufacturers who need to monitor water levels in their operations, but don’t want to spend a lot of money on expensive equipment.

Overall, pressure sensors are revolutionizing the way manufacturers measure water levels in their operations. Pressure sensors are highly accurate, reliable, and cost-effective, making them an ideal choice for manufacturers who need to monitor water levels in their operations. With pressure sensors, manufacturers can accurately and reliably measure the water levels in their tanks, ensuring that their operations run smoothly and efficiently.

The accuracy of pressure sensors makes them ideal for manufacturers who need to monitor water levels in their operations. Pressure sensors are able to measure the water level in a tank with an accuracy of up to 0.1%, which is far more accurate than traditional methods of measuring water levels. This accuracy ensures that manufacturers can accurately monitor the water levels in their tanks, and can take action if the levels become too high or too low.

The reliability of pressure sensors also makes them an ideal choice for manufacturers. Pressure sensors are designed to be highly durable and reliable, and can withstand extreme temperatures and pressures. This ensures that manufacturers can rely on their pressure sensors to accurately measure the water levels in their tanks, even in the most extreme conditions.

Finally, pressure sensors are also cost-effective. Pressure sensors are relatively inexpensive, and can be easily installed in a tank or other container. This makes them an ideal choice for manufacturers who need to monitor water levels in their operations, but don’t want to spend a lot of money on expensive equipment.

Overall, pressure sensors are revolutionizing the way manufacturers measure water levels in their operations. Pressure sensors are highly accurate, reliable, and cost-effective, making them an ideal choice for manufacturers who need to monitor water levels in their operations. With pressure sensors, manufacturers can accurately and reliably measure the water levels in their tanks, ensuring that their operations run smoothly and efficiently.The Benefits of Using Pressure Sensors for Accurate Water Level Measurement in Manufacturing

Pressure sensors are an invaluable tool for accurate water level measurement in manufacturing. Pressure sensors are designed to measure the pressure of a liquid or gas, and can be used to measure the level of water in a tank or other container. Pressure sensors are highly accurate and reliable, and can be used to measure water levels in a variety of applications. The most common use of pressure sensors for water level measurement is in industrial processes. Pressure sensors can be used to measure the level of water in tanks, pipes, and other containers. This is especially useful in manufacturing processes, where accurate water levels are essential for efficient operation. Pressure sensors can be used to measure the level of water in tanks, pipes, and other containers, and can be used to monitor the water levels in a variety of applications. Pressure sensors are also used to measure the level of water in tanks and other containers in residential and commercial applications. Pressure sensors can be used to measure the level of water in swimming pools, hot tubs, and other water-filled containers. Pressure sensors can also be used to measure the level of water in wells, ponds, and other water sources. Pressure sensors can be used to monitor the water levels in a variety of applications, and can be used to ensure that the water levels remain within acceptable levels.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |