Table of Contents

Exploring the Benefits of Pressure Sensor Simulink for Chinese Companies

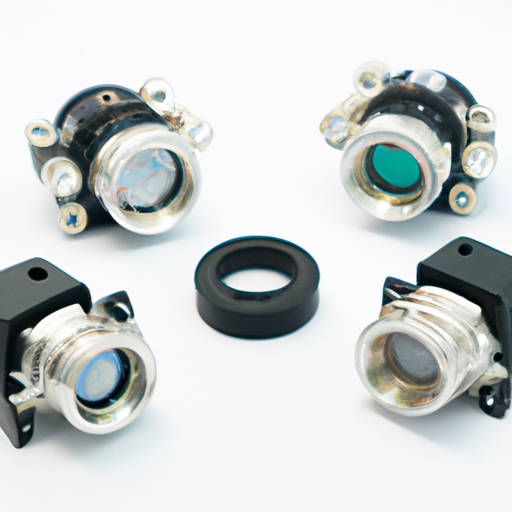

The use of pressure sensors in Simulink is becoming increasingly popular in China, and for good reason. Pressure sensors are used to measure the pressure of a fluid or gas, and Simulink is a powerful software tool that can be used to simulate and analyze the behavior of complex systems. By combining the two, Chinese companies can gain a number of benefits.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |

First, pressure sensors in Simulink can help Chinese companies save time and money. By using Simulink to simulate the behavior of a system, companies can quickly identify potential problems and make adjustments before they become costly. This can help reduce the amount of time and money spent on costly repairs and maintenance.

Second, pressure sensors in Simulink can help Chinese companies improve the accuracy of their measurements. By using Simulink to simulate the behavior of a system, companies can ensure that their measurements are accurate and reliable. This can help them make better decisions and improve the quality of their products.

First, pressure sensors in Simulink can help Chinese companies save time and money. By using Simulink to simulate the behavior of a system, companies can quickly identify potential problems and make adjustments before they become costly. This can help reduce the amount of time and money spent on costly repairs and maintenance.

Second, pressure sensors in Simulink can help Chinese companies improve the accuracy of their measurements. By using Simulink to simulate the behavior of a system, companies can ensure that their measurements are accurate and reliable. This can help them make better decisions and improve the quality of their products.