How to Properly Connect a Pressure Transducer: A Guide for Chinese High-Grade Companies

Pressure transducers are essential components in many industries, including manufacturing, automotive, and aerospace. These devices are used to measure and monitor pressure levels in various systems, providing crucial data for process control and safety. For Chinese high-grade companies, it is crucial to understand how to properly connect a pressure transducer to ensure accurate and reliable measurements. The first step in connecting a pressure transducer is to identify the correct electrical connections. Most pressure transducers have three electrical connections: power supply, ground, and signal output. The power supply connection provides the necessary voltage for the transducer to operate, while the ground connection ensures a stable reference point for accurate measurements. The signal output connection is where the transducer sends the measured pressure data to the monitoring or control system. Once the electrical connections are identified, it is important to ensure proper wiring. Chinese high-grade companies should use high-quality cables and connectors to minimize signal interference and ensure reliable data transmission. It is also crucial to follow the manufacturer’s instructions regarding wire gauge and length to avoid voltage drops and signal degradation.

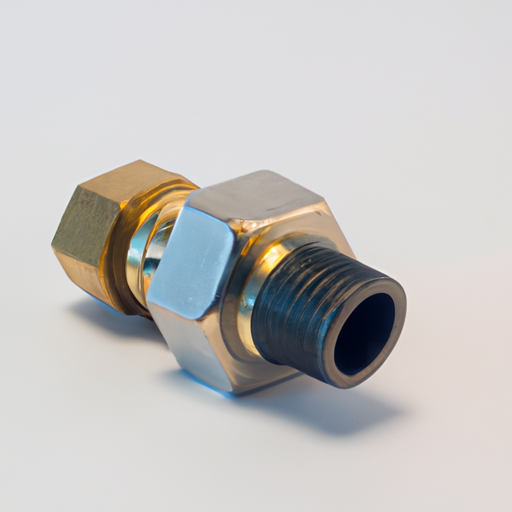

After the electrical connections are established, the next step is to connect the pressure transducer to the system being monitored. This involves selecting the appropriate fittings and adapters to ensure a secure and leak-free connection. Chinese high-grade companies should carefully choose materials that are compatible with the system’s media and operating conditions to prevent corrosion or contamination.

When connecting the pressure transducer, it is important to consider the orientation and mounting position. The transducer should be installed in a location that allows for easy access and maintenance while minimizing exposure to excessive vibration or temperature fluctuations. Chinese high-grade companies should also ensure that the transducer is properly aligned with the system’s pressure port to avoid measurement errors caused by misalignment.

Once the pressure transducer is connected, it is crucial to verify its performance and calibration. Chinese high-grade companies should follow the manufacturer’s instructions for initial setup and calibration procedures. This may involve applying a known pressure source and comparing the transducer’s output to the expected values. Regular calibration checks should also be performed to ensure ongoing accuracy and reliability.

After the electrical connections are established, the next step is to connect the pressure transducer to the system being monitored. This involves selecting the appropriate fittings and adapters to ensure a secure and leak-free connection. Chinese high-grade companies should carefully choose materials that are compatible with the system’s media and operating conditions to prevent corrosion or contamination.

When connecting the pressure transducer, it is important to consider the orientation and mounting position. The transducer should be installed in a location that allows for easy access and maintenance while minimizing exposure to excessive vibration or temperature fluctuations. Chinese high-grade companies should also ensure that the transducer is properly aligned with the system’s pressure port to avoid measurement errors caused by misalignment.

Once the pressure transducer is connected, it is crucial to verify its performance and calibration. Chinese high-grade companies should follow the manufacturer’s instructions for initial setup and calibration procedures. This may involve applying a known pressure source and comparing the transducer’s output to the expected values. Regular calibration checks should also be performed to ensure ongoing accuracy and reliability.

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |