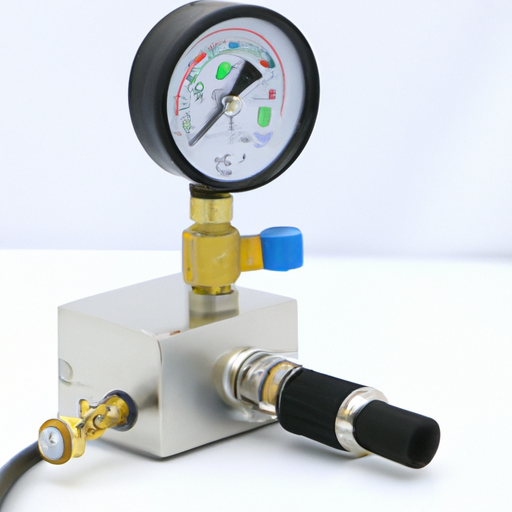

Introduction to Pressure Transducers

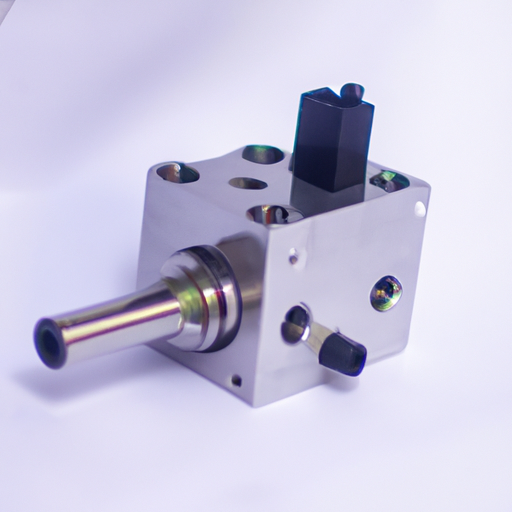

Pressure Transducers are an essential component in many industries, including manufacturing, automotive, and aerospace. These devices are used to measure and monitor pressure levels in various systems and processes. In this article, we will introduce you to pressure transducers and discuss their importance in different applications. A pressure transducer, also known as a pressure sensor, is a device that converts pressure into an electrical signal. It consists of a sensing element, which is typically a diaphragm or a piezoelectric crystal, and an electronic circuit that amplifies and converts the signal into a readable format. The sensing element deforms under the influence of pressure, causing a change in resistance, capacitance, or voltage, which is then measured and converted into a pressure reading. Pressure transducers are used in a wide range of applications, from simple pressure monitoring to complex control systems. In the manufacturing industry, they are used to monitor and control pressure in hydraulic and pneumatic systems, ensuring optimal performance and safety. In the automotive industry, pressure transducers are used in fuel injection systems, tire pressure monitoring systems, and engine management systems. They play a crucial role in maintaining fuel efficiency and reducing emissions. In the aerospace industry, pressure transducers are used in aircraft engines, hydraulic systems, and cabin pressure control systems. They help ensure the safety and efficiency of flight operations. Pressure transducers are also used in medical equipment, such as ventilators and blood pressure monitors, where accurate pressure measurements are critical for patient care. When it comes to choosing a pressure transducer, it is important to consider factors such as the range of pressure to be measured, the accuracy required, and the environmental conditions in which the transducer will be used. Different types of pressure transducers are available, including piezoresistive, capacitive, and piezoelectric transducers. Each type has its own advantages and limitations, and the choice depends on the specific application requirements.

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |