Table of Contents

Exploring the Benefits of Pressure Transducer vs Transmitter Factory Solutions

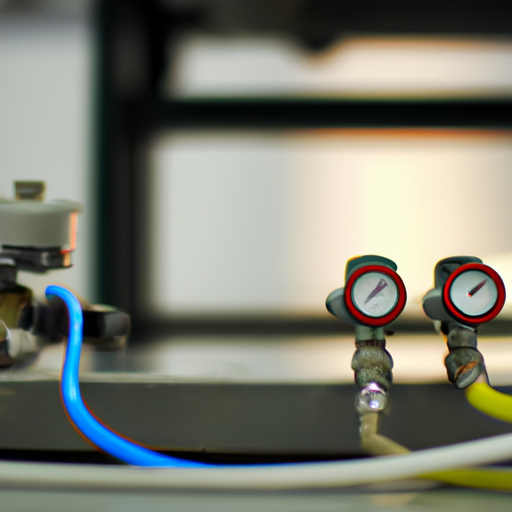

When it comes to measuring pressure, there are two main solutions available: pressure transducers and transmitters. Both of these solutions offer a range of benefits, but it is important to understand the differences between them in order to make the best choice for your application. Pressure transducers are designed to measure pressure and convert it into an electrical signal. This signal can then be used to control or monitor a system. Pressure transducers are typically more accurate than transmitters, and they are also more cost-effective. Additionally, they are easy to install and maintain, making them a great choice for many applications.

Transmitters, on the other hand, are designed to measure pressure and transmit it to a remote location. This allows for more accurate readings and better control over the system. Transmitters are also more expensive than transducers, but they are often more reliable and can be used in more complex applications.

Pressure transducers are designed to measure pressure and convert it into an electrical signal. This signal can then be used to control or monitor a system. Pressure transducers are typically more accurate than transmitters, and they are also more cost-effective. Additionally, they are easy to install and maintain, making them a great choice for many applications.

Transmitters, on the other hand, are designed to measure pressure and transmit it to a remote location. This allows for more accurate readings and better control over the system. Transmitters are also more expensive than transducers, but they are often more reliable and can be used in more complex applications.

Comparing the Cost-Effectiveness of Pressure Transducer vs Transmitter Factory Solutions

When it comes to cost-effectiveness, pressure transducers and transmitters are two of the most popular factory solutions. Both offer reliable and accurate readings, but which one is the most cost-effective? Pressure transducers are typically the more cost-effective option. They are relatively inexpensive to purchase and install, and they require minimal maintenance. They are also highly accurate and reliable, making them a great choice for many applications.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |