Table of Contents

Benefits of Using HART Communicator for Pressure Transmitter Calibration

Pressure transmitter calibration is a critical process in ensuring the accuracy and reliability of pressure measurement instruments. Calibration is necessary to ensure that the transmitter is providing accurate and consistent readings, which is essential for maintaining the safety and efficiency of industrial processes. One of the most effective tools for pressure transmitter calibration is the HART communicator. HART (Highway Addressable Remote Transducer) communicator is a communication protocol that allows for two-way communication between field devices and control systems. It is widely used in the process industry for configuring, monitoring, and diagnosing field devices such as pressure transmitters. The HART communicator provides a user-friendly interface that allows technicians to easily access and adjust the settings of the transmitter.How to Choose the Best Factory in China for Pressure Transmitter Calibration with HART Communicator

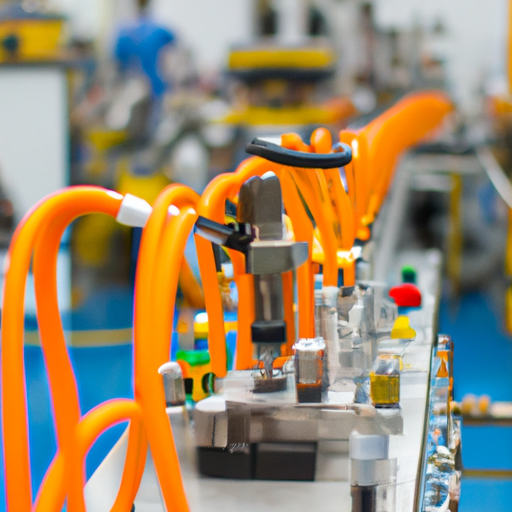

Pressure transmitter calibration is a critical process in ensuring the accuracy and reliability of pressure measurement instruments. With the advancement of technology, the use of HART communicators has become increasingly popular for calibrating pressure transmitters. These devices allow for digital communication with the transmitter, making the calibration process more efficient and accurate. When it comes to choosing a factory in China for pressure transmitter calibration with HART communicator, there are several factors to consider. The first and most important factor is the factory’s reputation and track record. It is essential to choose a factory that has a proven track record of providing high-quality calibration services for pressure transmitters. This can be determined by looking at customer reviews and testimonials, as well as the factory’s certifications and accreditations. Another important factor to consider is the factory’s experience and expertise in pressure transmitter calibration. It is crucial to choose a factory that has a team of highly skilled and experienced technicians who are knowledgeable about the calibration process and can ensure accurate and reliable results. Additionally, the factory should have state-of-the-art equipment and facilities to perform the calibration process effectively. In addition to reputation and expertise, it is also essential to consider the factory’s pricing and turnaround time. It is important to choose a factory that offers competitive pricing for their calibration services while also providing quick turnaround times. This will ensure that your pressure transmitters are calibrated efficiently and cost-effectively. Furthermore, it is important to consider the factory’s customer service and support. A reputable factory should have a dedicated customer service team that is available to answer any questions or concerns you may have about the calibration process. They should also provide ongoing support and assistance to ensure that your pressure transmitters are functioning correctly after calibration. When choosing a factory in China for pressure transmitter calibration with HART communicator, it is also important to consider the factory’s location and accessibility. It is advisable to choose a factory that is conveniently located and easily accessible, as this will make it easier to transport your pressure transmitters to and from the factory for calibration.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |