Table of Contents

Benefits of Pressure Transmitter Testing in Ensuring Product Quality

Pressure transmitter testing is a crucial step in ensuring the quality and reliability of these essential devices. In China, there are many good factories that specialize in producing pressure transmitters, and they understand the importance of thorough testing to meet industry standards and customer expectations. One of the key benefits of pressure transmitter testing is the assurance of accuracy. These devices are used in a wide range of industries, from manufacturing to oil and gas, where precise measurements are critical for safety and efficiency. By subjecting pressure transmitters to rigorous testing procedures, manufacturers can verify that they meet the required specifications and provide accurate readings under various operating conditions. In addition to accuracy, pressure transmitter testing also helps to identify any potential defects or malfunctions in the devices. This is especially important in industries where even a small error in measurement can have serious consequences. By conducting thorough testing, manufacturers can detect and address any issues before the products are shipped to customers, ensuring that only high-quality and reliable pressure transmitters are delivered. Furthermore, pressure transmitter testing can help manufacturers optimize their production processes and improve product performance. By analyzing the results of testing, manufacturers can identify areas for improvement in design, materials, or manufacturing techniques. This continuous feedback loop allows for ongoing refinement and innovation, leading to better products that meet the evolving needs of customers. Another benefit of pressure transmitter testing is the validation of compliance with industry standards and regulations. In highly regulated industries such as aerospace or pharmaceuticals, pressure transmitters must meet strict requirements for accuracy, reliability, and safety. By conducting thorough testing, manufacturers can demonstrate that their products adhere to these standards, giving customers confidence in the quality and reliability of the devices. Moreover, pressure transmitter testing can also help manufacturers identify opportunities for cost savings and efficiency improvements. By identifying and addressing any inefficiencies or weaknesses in the production process, manufacturers can reduce waste, improve productivity, and ultimately lower costs. This not only benefits the manufacturer but also allows them to offer competitive pricing to customers without compromising on quality.How to Choose a Reliable Pressure Transmitter Testing Factory in China

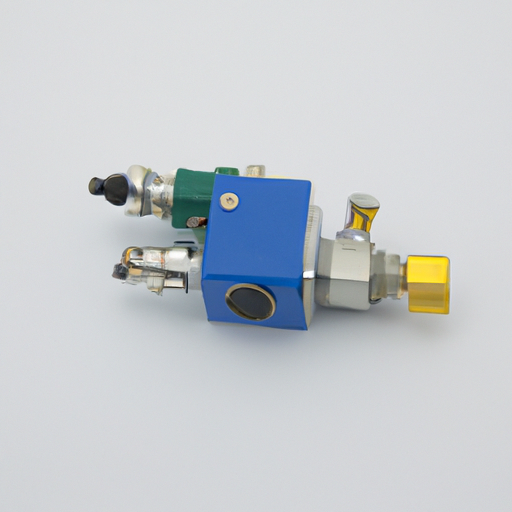

Pressure transmitters are essential components in various industries, as they play a crucial role in measuring and monitoring pressure levels in different systems. When it comes to choosing a reliable pressure transmitter testing factory in China, there are several factors that you need to consider to ensure that you get high-quality products that meet your specific requirements. One of the most important factors to consider when selecting a pressure transmitter testing factory in China is the factory’s reputation. A good factory will have a solid reputation for producing high-quality products that meet industry standards. You can check the factory’s reputation by reading reviews from previous customers or by asking for recommendations from industry experts. In addition to reputation, you should also consider the factory’s experience and expertise in pressure transmitter testing. A factory that has been in the industry for many years and has a team of experienced technicians is more likely to provide reliable and accurate testing services. Make sure to inquire about the factory’s testing procedures and equipment to ensure that they can meet your specific testing requirements.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |