Table of Contents

Understanding the Working Principle of Pressure Transmitters

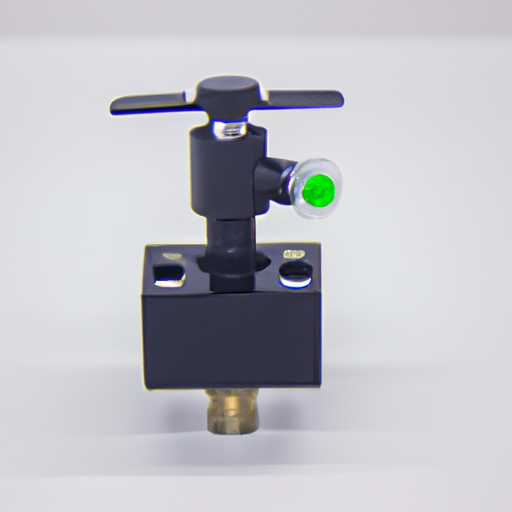

Pressure transmitters are essential devices used in various industries to measure and transmit pressure readings accurately. Understanding the working principle of pressure transmitters is crucial for ensuring their proper functioning and reliability in industrial applications. In this article, we will delve into the working principle of pressure transmitters and explore how they operate to provide accurate pressure measurements. Pressure transmitters work on the principle of converting the pressure exerted on a sensing element into an electrical signal. The sensing element, typically a diaphragm or a Bourdon tube, deforms in response to the applied pressure. This deformation causes a change in the resistance, capacitance, or voltage of the sensing element, which is then converted into an electrical signal by the transmitter. One of the key components of a pressure transmitter is the pressure sensor, which is responsible for detecting the pressure changes and converting them into electrical signals. The pressure sensor is connected to a signal conditioning circuit, which amplifies and processes the electrical signals to ensure accurate and reliable pressure measurements. The signal conditioning circuit in a pressure transmitter plays a crucial role in filtering out noise and interference from the electrical signals, ensuring that only the relevant pressure readings are transmitted. The processed signals are then sent to the output circuit, where they are converted into a standardized output signal, such as 4-20 mA or 0-10 V, for transmission to the control system. Pressure transmitters are available in various types, including absolute, gauge, and differential pressure transmitters, each designed for specific applications. Absolute pressure transmitters measure pressure relative to a perfect vacuum, while gauge pressure transmitters measure pressure relative to atmospheric pressure. Differential pressure transmitters measure the difference in pressure between two points in a system. In industrial applications, pressure transmitters are used in a wide range of processes, such as monitoring and controlling pressure in pipelines, tanks, and vessels. They are also used in HVAC systems, hydraulic systems, and pneumatic systems to ensure optimal performance and efficiency. Chinese suppliers are known for their high-quality pressure transmitters that are reliable, accurate, and cost-effective. Chinese pressure transmitter suppliers offer a wide range of products to meet the diverse needs of industries, from small-scale applications to large-scale industrial processes.Finding Reliable Chinese Suppliers for Pressure Transmitters in Tamil Nadu

Pressure transmitters are essential components in various industries, including manufacturing, oil and gas, and automotive. These devices play a crucial role in measuring and transmitting pressure readings accurately. If you are in Tamil Nadu and looking for reliable Chinese suppliers for pressure transmitters, it is essential to understand the working principle of these devices. The working principle of a pressure transmitter is relatively simple yet effective. These devices consist of a sensing element, a signal conditioning circuit, and a transmitter. The sensing element, typically a diaphragm or a bourdon tube, deforms in response to changes in pressure. This deformation is then converted into an electrical signal by the signal conditioning circuit. The transmitter amplifies and transmits this signal to a control system for further processing.| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |