Table of Contents

How Pressure Sensors Transducers are Used in Industrial Manufacturing

Pressure sensors transducers are widely used in industrial manufacturing to measure and monitor pressure in a variety of applications. These sensors are used to measure the pressure of liquids, gases, and vapors, and can be used to detect changes in pressure over time. Pressure sensors transducers are used to measure the pressure of a system, such as a hydraulic system, and can be used to detect changes in pressure over time. They can also be used to detect changes in pressure in a system, such as a pneumatic system, and can be used to detect changes in pressure in a system, such as a steam system. Pressure sensors transducers are also used to measure the pressure of a system, such as a hydraulic system, and can be used to detect changes in pressure over time. They can also be used to detect changes in pressure in a system, such as a pneumatic system, and can be used to detect changes in pressure in a system, such as a steam system. Pressure sensors transducers are also used to measure the pressure of a system, such as a hydraulic system, and can be used to detect changes in pressure over time. In addition, pressure sensors transducers are used to measure the pressure of a system, such as a hydraulic system, and can be used to detect changes in pressure over time. They can also be used to detect changes in pressure in a system, such as a pneumatic system, and can be used to detect changes in pressure in a system, such as a steam system. Pressure sensors transducers are also used to measure the pressure of a system, such as a hydraulic system, and can be used to detect changes in pressure over time.The Benefits of Using Pressure Sensors Transducers in Industrial Manufacturing

Pressure sensors transducers are an invaluable tool in industrial manufacturing, offering a range of benefits that make them a must-have for any production line. Compared to traditional pressure gauges, pressure sensors transducers offer a number of advantages that make them the preferred choice for many industrial applications. First and foremost, pressure sensors transducers are much more accurate than traditional pressure gauges. This is because they are able to measure pressure with a much higher degree of precision, allowing for more accurate readings and better control over the manufacturing process. Additionally, pressure sensors transducers are able to measure pressure over a much wider range of values, making them ideal for applications that require a wide range of pressure readings.

Another benefit of pressure sensors transducers is that they are much more reliable than traditional pressure gauges. This is because they are able to withstand extreme temperatures and pressures, making them ideal for use in harsh industrial environments. Additionally, pressure sensors transducers are much more durable than traditional pressure gauges, meaning they can be used for longer periods of time without needing to be replaced.

First and foremost, pressure sensors transducers are much more accurate than traditional pressure gauges. This is because they are able to measure pressure with a much higher degree of precision, allowing for more accurate readings and better control over the manufacturing process. Additionally, pressure sensors transducers are able to measure pressure over a much wider range of values, making them ideal for applications that require a wide range of pressure readings.

Another benefit of pressure sensors transducers is that they are much more reliable than traditional pressure gauges. This is because they are able to withstand extreme temperatures and pressures, making them ideal for use in harsh industrial environments. Additionally, pressure sensors transducers are much more durable than traditional pressure gauges, meaning they can be used for longer periods of time without needing to be replaced.

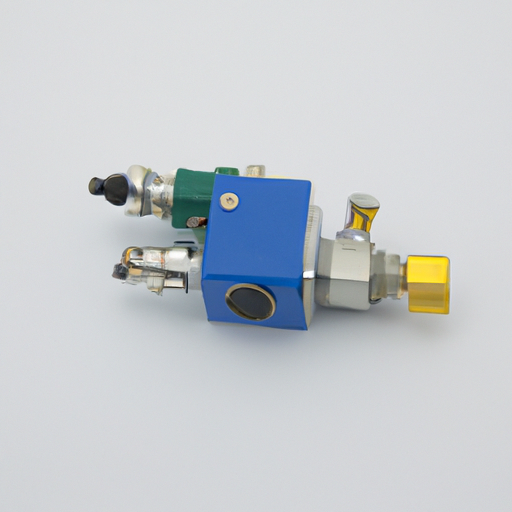

| Measuring medium | Gases, vapours, liquids |

| Inaccuracy | ±0.075% |

| stability | ±0.1%/3 years |